Z6_EL9QHKG10GPM20IJGE61AK10O0

Z7_I8001C80M82D40A3IJJSN11012

S2K Commerce - Products Dropdown

- ${title}

Loading...

Z7_I8001C80MOVHE0AP2AJ17A3084

S2K Commerce - Shopping Cart

- ${title}

Loading...

Z7_EL9QHKG10GPM20IJGE61AK10S5

S2K Commerce - Order Entry

- ${title}

Loading...

Home

>

EOAT for Cobots

>

Quick Changers

>

Automatic Quick Changer - SmartShift

> 8469 SmartShift HD63 Automatic Quick Changer,

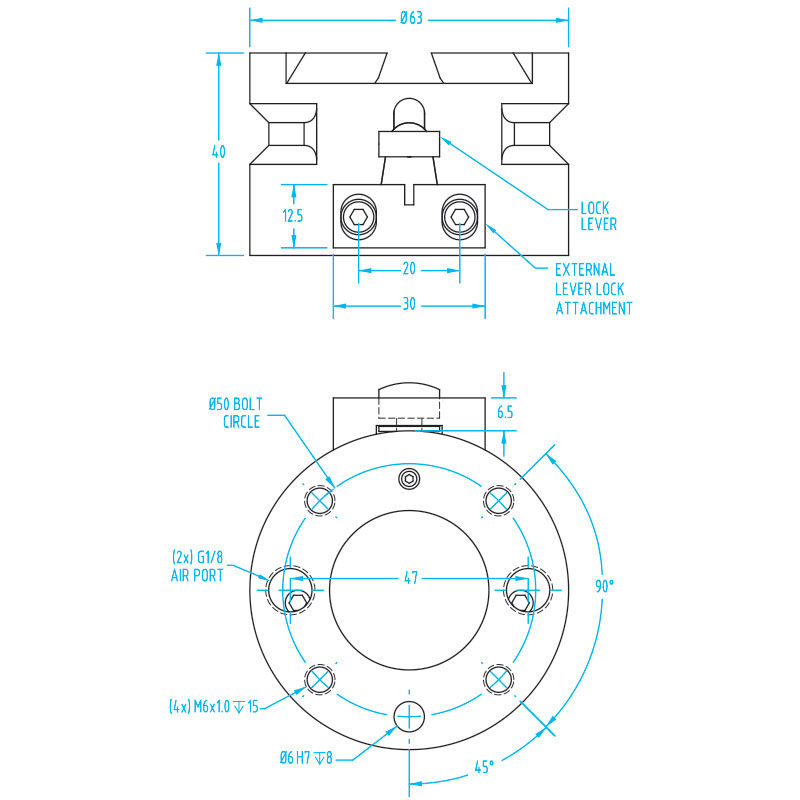

8469 SmartShift HD63 Automatic Quick Changer, Tool Side (EOAT Side)

Item #:SS 2600

Available: In Stock

SmartShift HD63: Higher payload and added safety features!

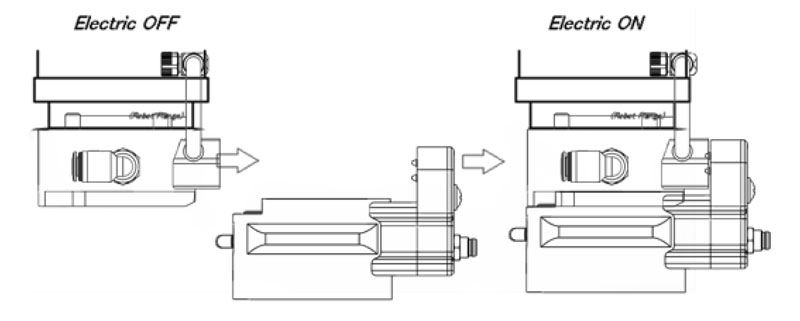

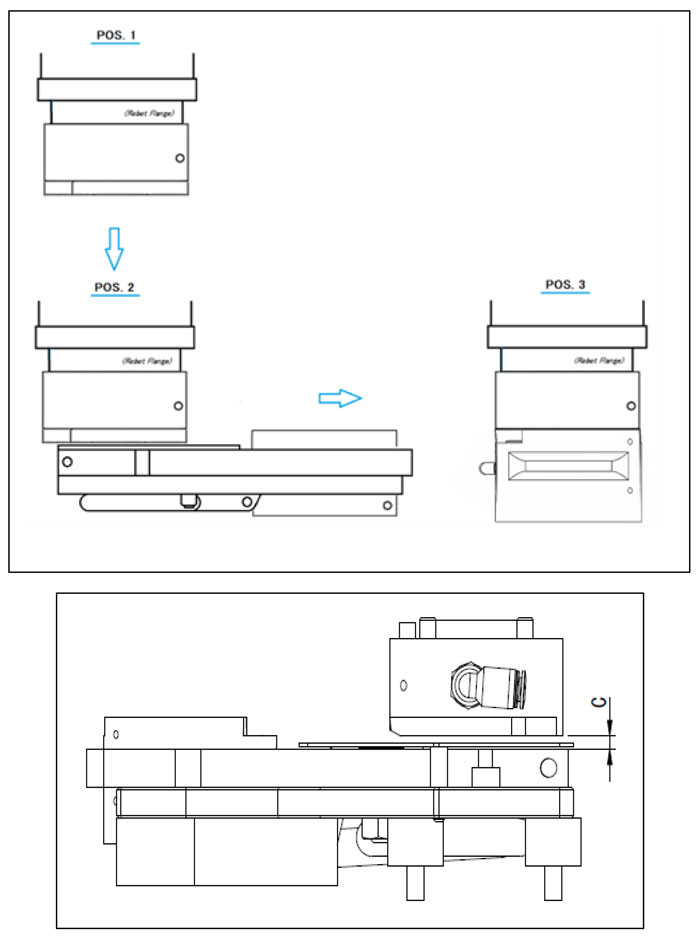

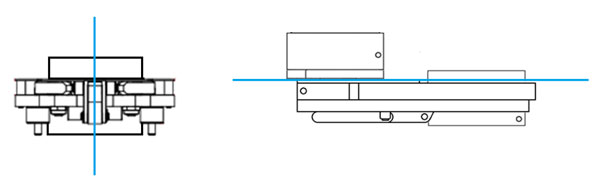

The HD63 version uses the same principle as the standard (Gen III) SmartShift and even uses the same pneumatic and electrical accessories. Here are a few features that set it apart and make it suitable for higher payload applications. Automatic Tool Changers require some level of added integration, and we encourage you to partner with our EOAT Engineers to ensure a seamless implementation.

475.00

Each

Quantity:

HD63 Features:

- HD63 robot side is made from hard-anodized aluminum and a robust locking latch strike insert.

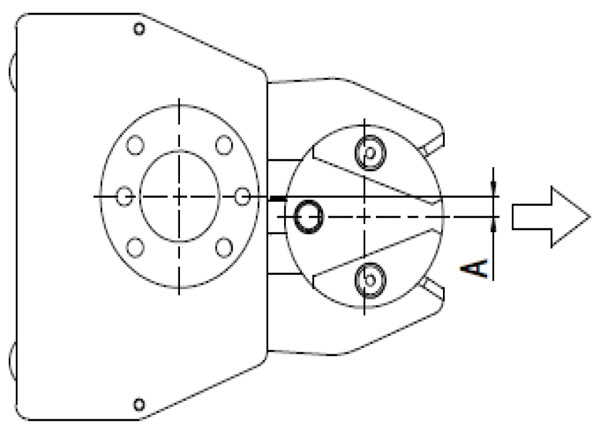

- The tool pocket for larger, heavier tools includes slotted receiver for the recommended stabilizer plates (Q#8490 & Q#8491).

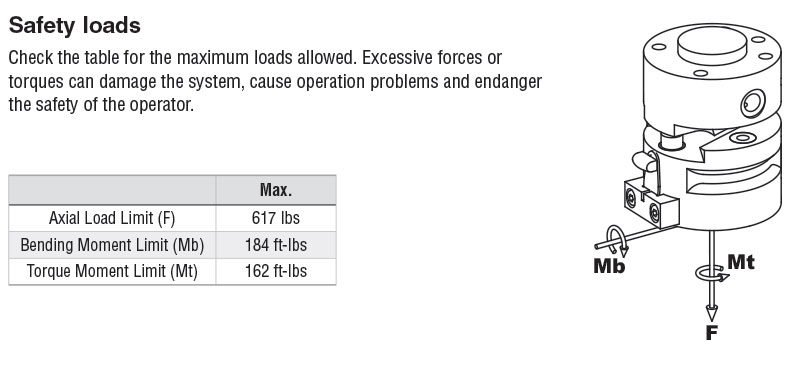

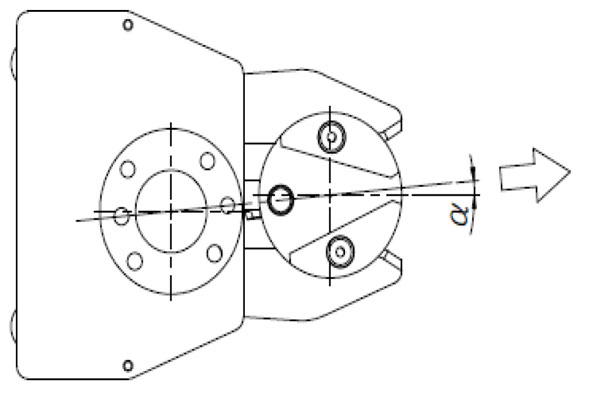

- With an added secondary safety latch, the tool side HD63 ensure the tool can only be released when it is securely nested into the tool pocket.

- Note that the HD63 tool side with the safety latch is not compatible with the Gen III (standard) SmartShift version and requires the HD63 Tool Pocket (Q#8470).

- 282g

- EMI suggested payload: 165.3lbs (75kg)* *Manufacturer specified max. payload: 150kg. Not recommended for collaborative applications. Contact EMI Engineering.

- Metal construction for even more stability.

- Safety lever to engage/disengage.

- Uses the same accessories for pneumatic and electric expansion.

- Tool Pocket now can be enhanced with stabilizer plates for regular or manifold-mounted tools

- Includes mounting hardware.

- No electricity required when changing tools via unique wedge mount.

- Equipped with an air interface allowing easy mounting of many end effectors

- Reference SmartShift: 2600