S2K Commerce - Shopping Cart

- ${title}

S2K Commerce - Products Dropdown

- ${title}

Web Content Viewer

- ${title}

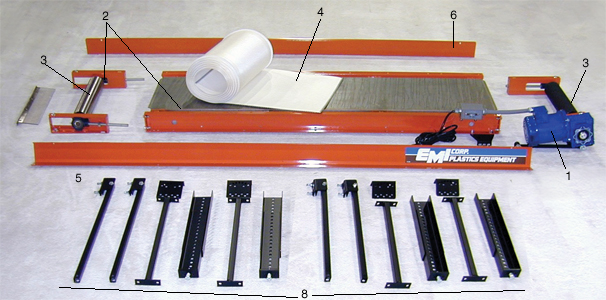

Signature Line Steel Frame Conveyors

Signature Line steel frame conveyors give you a cost-effective way to build an automation system — these strong, heavy-duty conveyors can meet your requirements today and be adapted to your future needs.

Main Features:

- Steel frame for maximum heavy-duty industrial wear

- Direct Drive Package: The motor and SEALED GEAR REDUCER attach directly to the pulley shaft, minimizing maintenance.

- 4-40 FPM Variable Speed Drive

- No roller chain or sprockets to align

- 150 lbs. maximum load

- Leg Sets and Castors included

- Double V-Guide Belt Tracking: Provides exceptionally stable belt tracking, which significantly extends belt life.

Guides are on the sides rather than the middle make it easier to track the belt.

Specifications:

1. Drive Package: Includes a 1/3 hp 110V input AC TEFC motor with a 4-40 FPM variable speed controller. The gear reducer is sealed and permanently lubricated requiring no service. Power transmission is provided via direct drive configuration. 15' of SJ cord with a standard three-prong plug is pre-wired to the starter. Control wiring is contained in liquid-tight conduit and connectors. Drive packages 3'–30' long have 150 lb. maximum load.

2. Belt Guidance: True Track Belt Guidance System comes standard on 3'–30' long conveyors. Using a Double V-guide slot in the frame, 1/4" wall crowned pulleys, and bonded Double V-guide belting, “True Track” minimizes belt run off and reduces belt tracking maintenance.

3. Pulleys: To ensure long lived operation, 3.5" diameter crowned pulleys incorporate 1" diameter shafts, self aligning sealed ball bearings with eccentric locking collars, telescopic take-up adjustment, position locking nuts, and Zerk grease fittings.

4. Belting: Our easy to clean, FDA approved, white, PVC belting with staple-type belt lacing (which prevents lacing pullout and splice failure), makes belt maintenance quick and easy. Inclined conveyors have a bottom cleat support plate and bonded flexible cleats that have no bolts or rivets that may tear out.

5. Frame: Our sturdy, reinforced, welded, cross-braced steel frames, powder coated safety orange (other colors are available) incorporate 12-gauge channels with a 16-gauge slide bed to minimize twist and camber, and provide longer service life.

6. Rails: To ensure molded pieces do not get pinched, damaged, or lost between the rail and belt, we place our 12-gauge steel 4" rails so that they overlap the belt. To keep your molded parts contained on the infeed end of the conveyor, we include an infeed-end backpiece.

7. Shipment: Generally conveyors 3'–10' are shipped fully assembled, pre-wired, tested, and ready to run (legs must be attached). Conveyors 11' and over are shipped partially assembled to minimize shipping damage. Some frame and belt assembly is required; drive packages and system panels are pre-assembled and tested. For your convenience, arrangements can be made for longer conveyors to be shipped assembled.

8. Leg Sets: Adjustable leg sets and locking swivel castors are standard (not included) on RM and RMC conveyors. Belt height must be specified.