S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

Web Content Viewer

- ${title}

Parts Containment Options for Conveyor Systems

EMI provides many Parts Containment options – Lane Diverters, Hinged Side Rails, Side Belt Guards and More!

EMI offers a complete line of Parts Containment options for your application. Hinged Side Rails, or a Side feed, under press hopper are low cost options that eliminate the need for an under-press conveyor. They can be used when under press space is limited or when there are obstructions. Vibrators, air blowers, or Teflon® lining can be used to help assure that parts move consistently. The addition of low profile, side mounted castors allows it to be rolled easily under the press. Hinged side rails simply fold in, out of the way, when the conveyor is positioned, they fold out when it's in place. This allows a narrow, more maneuverable conveyor to be used, yet still provides an effectively wide parts receiving area. Rail heights are customized to fit your application, and easily adjusted if it should change.

Lane Diverters Segregate Parts:

Lane diverters can be added to almost any EMI conveyor to segregate different parts and keep them apart during the conveying process. And excellent choice when segregating different parts from family molds or for conveying parts and runners to different processes or containers. Parts can be robotically placed onto the correct lane or diverted to the correct lane using either a diverter or a part / runner separator.

Click image for larger detailAdjustable Parts Receiving Tray & Cart:

Preventing pile ups at the end of a conveyor is easy with this adjustable angle cart. Placed at the end of a conveyor, this easy to adjust cart allows parts to slide away from the end of the conveyor. Not only does this help protect parts from being damaged by oncoming parts, it also helps to prevent parts from being drawn around and into the conveyor mechanism. Available in Stainless Steel, painted steel or aluminum. Wide range of sizes available.

An adjustable tray mounted at the end of a conveyor not only reduces spillage by positioning the box closer to the conveyor, it also helps to assure that boxes stay clean and dry by keeping them off the floor.

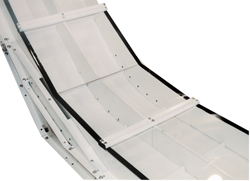

Sidewall Belting with cover rails keeps small parts & scrap on the belt:

Adding EMI's Corrugated Sidewall Belting to your belt conveyor will keep small parts from hanging up on the side rails or jamming between the side rails and the belt. The cover rails keep parts from getting behind the belt.

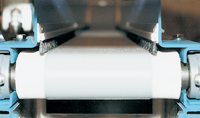

Side Belt Guards:

Provide a low-cost method of preventing parts or scrap from being trapped under side rails. Side belt guards are not available for Trim Line conveyors. As an alternate, consider brush Rail Guards. Note: Due to the friction this option may require a larger motor for the conveyor.

Hinged Side Rails:

When under press space is limited, or when there are obstructions, hinged rails can be added to the conveyor. Rails simply fold in, out of the way when the conveyor is positioned, then folded out when in place. This allows a narrower conveyor to be used yet still provides a wide area for parts receiving. Folding side rails can also be an excellent way to protect the conveyor when molds are frequently changed.

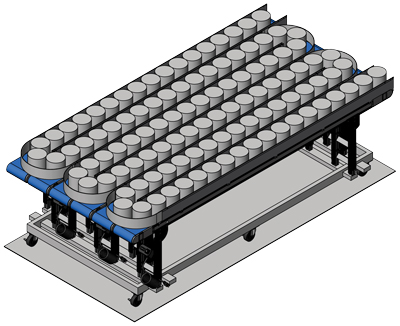

Four Lane Parts Diverter:

Separate conveyor lanes isolate mold cavities. If one section of the mold fails, only parts from that cavity need to be discarded. Chutes can be used to move parts beyond the normal range of a robot. They can also increase the speed of a robot by allowing it to release all four parts at once, without having to rotate the end-of-arm tooling.

Hinged Extension Rails:

Large Stainless steel hinged extension rails on an EAF conveyor with soft drop zone and internal drive EA-ID option.

Enclosures keep Contaminants Out:

Keep parts contained with side tails, polycarbonate windows and covers while cooling and detecting for metal. Find out more information about Enclosures.

Click images for larger detail