Z6_I8001C80MGFH50A5NPQ4Q39IJ3

Z7_I8001C80MGFH50A5NPQ4Q39UM6

S2K Commerce - Shopping Cart

- ${title}

Loading...

Z7_I8001C80MGFH50A5NPQ4Q39UM5

S2K Commerce - Products Dropdown

- ${title}

Loading...

Z7_I8001C80MGFH50A5NPQ4Q39UM7

Web Content Viewer

- ${title}

Loading...

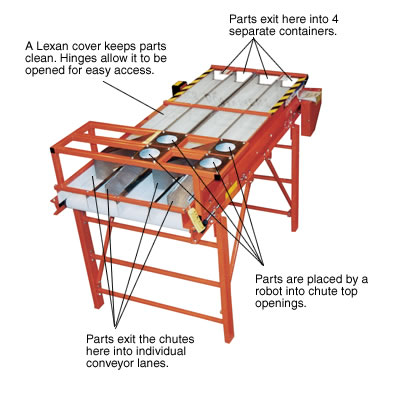

Chute-Style Robotic Parts Diverters

Chutes, which lead to divided lanes can be an excellent way to provide automation processes. In this application, parts are placed on the conveyor by a robot.

Benefits include:

- Cavity separation: Separate conveyor lanes isolate mold cavities—an excellent way to separate family molds

- Quality control: If one section of the mold fails, only parts from that cavity need to be discarded

- Extend robot range: Chutes can be used to move parts beyond the normal 'release' range of a robot

- Increase robot speed: Chutes can increase the speed of a robot by allowing it to release all 4 parts at once—without having to rotate the end-of-arm tooling

How does it work?

- A robot removes four parts at a time from the mold.

- It positions the parts over the four cut outs and releases them into the chutes.

- The parts move through the chutes to the four divided lanes.

- The conveyor moves them to the end and fills them into four separate containers.

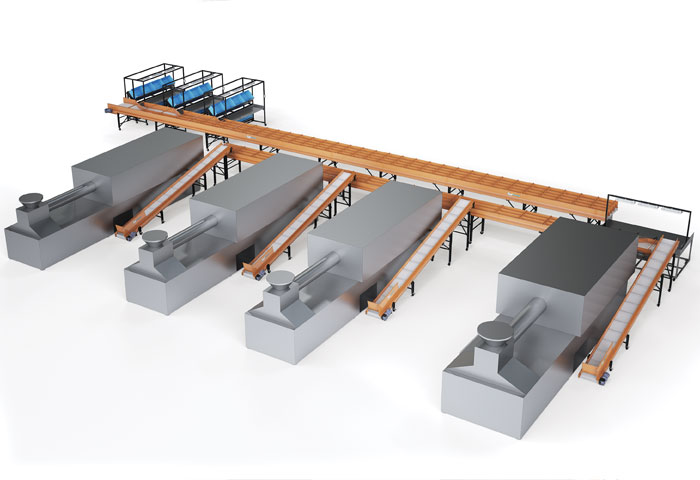

EMI’s Trunk Line Conveyors are built for plant-wide systems and incorporate rugged cross-bracing and sturdy construction for long distance runs. The end-mounted drives assure reliable belt tracking.

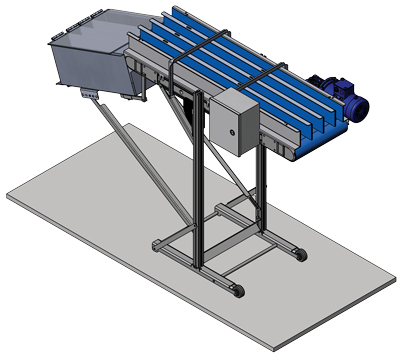

A Four Cavity Tooling drops parts onto this EAF with Lane Divider Package Conveyor which includes a catch tray

Dividers can have PVC belting or side belt guards to prevent parts from scratching and small part loss.

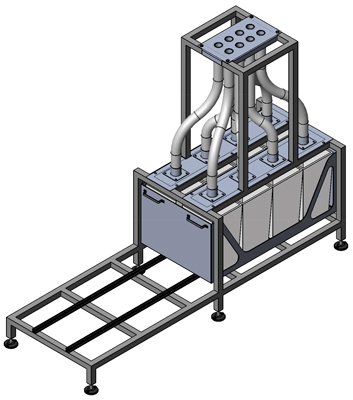

8-Chute Diverting Station with Flexible Tubing

Includes: Anti-static hose, Painted steel support frame, SST Tray for Boxes, and Leveling pads.