S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

Web Content Viewer

- ${title}

Conveyor Belting Options

EMI offers many types of belting options to suit a wide variety of applications

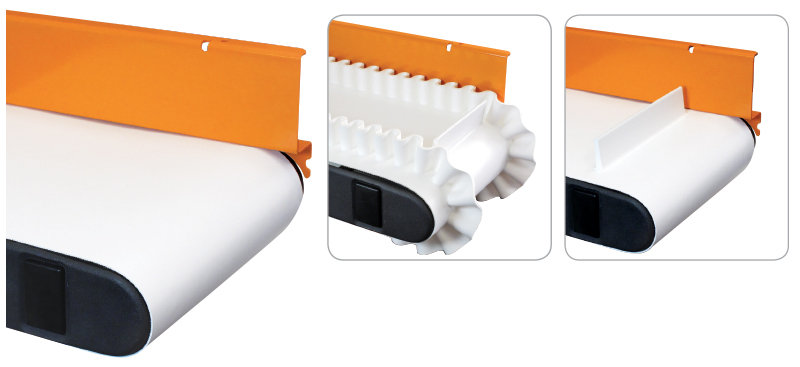

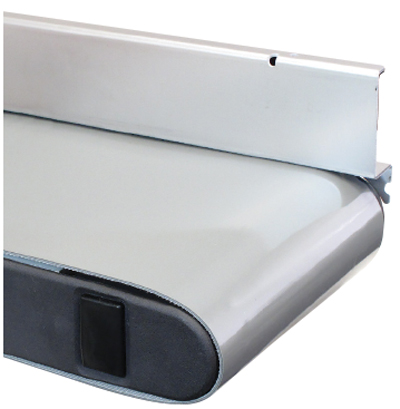

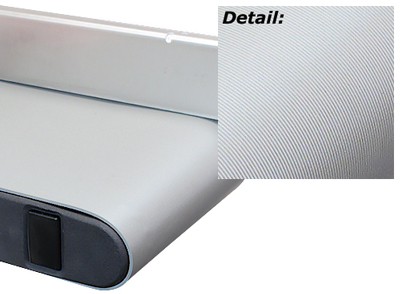

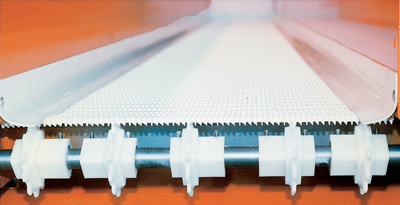

Our White PVC belt is standard on all EMI conveyors is an excellent general purpose belt. It is constructed using two plies of micro-filament/ multi-filament fabric with a FDA/USDA approved PVC cover. Its stretch resistance characteristics are far superior versus woven style materials. Available in different size cleat height and centers.

- Anti-static

- Non-marking

- Contact temperature range: 5°–210°F

- FDA/USDA approved for direct contact of unwrapped foodstuff.

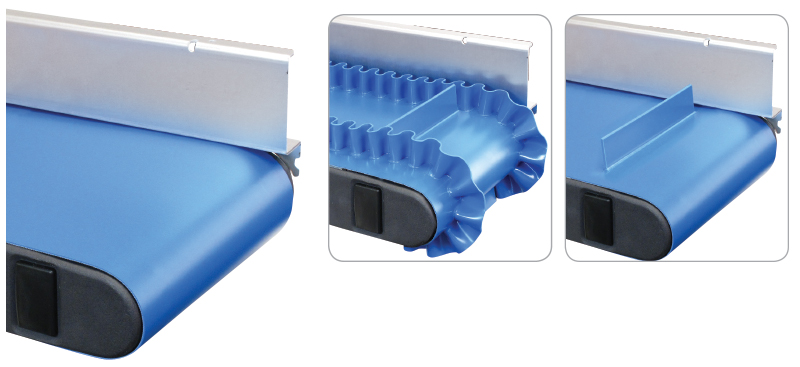

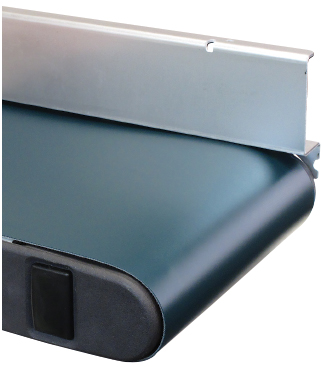

Our Blue PVC belt is standard on our Extruded Aluminum Conveyors. is an excellent general purpose belt. It is constructed using two plies of micro-filament/ multi-filament fabric with a FDA/USDA approved PVC cover. Its stretch resistance characteristics are far superior versus woven style materials. Available in different size cleat height and centers. (shown further down on page).

- Anti-static

- Non-marking

- Contact temperature range: 5°–210°F

- FDA/USDA approved for direct contact of unwrapped foodstuff.

Corrugated Sidewall Belting: Great for small parts containment when conveying flat or on an incline. This belting is plied, easily cleaned, and FDA approved. PVC belting is standard with staple belt lacing and 1.5" high flexible cleats on 18" centers. The flexible, corrugated sidewalls are 1.5" high. Alternate heights are available.

Corrugated Sidewall Belting: Great for small parts containment when conveying flat or on an incline. This belting is plied, easily cleaned, and FDA approved. PVC belting is standard with staple belt lacing and 1.5" high flexible cleats on 18" centers. The flexible, corrugated sidewalls are 1.5" high. Alternate heights are available.

Other Belting Options

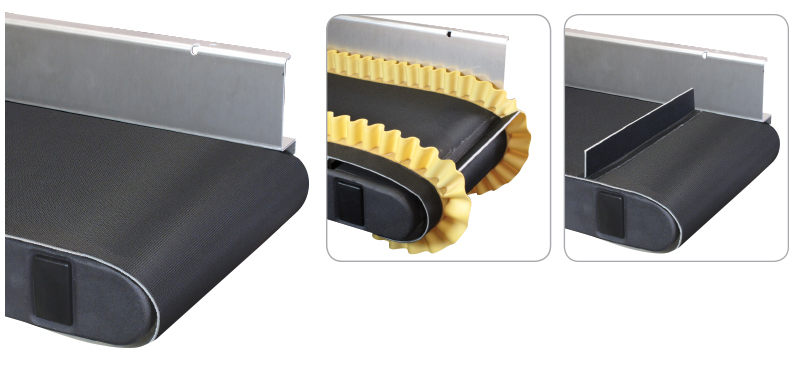

This 3-ply High-Temperature Polyester Belt is popular with heavy-duty applications that require a belt for rough textured or sharp edged parts. The corrugated side wall is made of foamed PU.

- 3-ply makes it very impact resistant

- Temperature range: -22°–194°F

- Short temperature range: -22°–356°F

- Industrial grade, not FDA

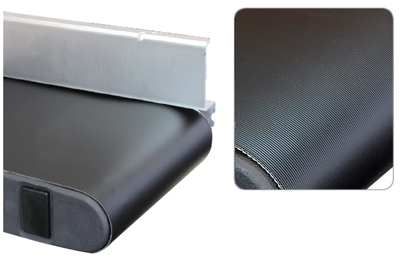

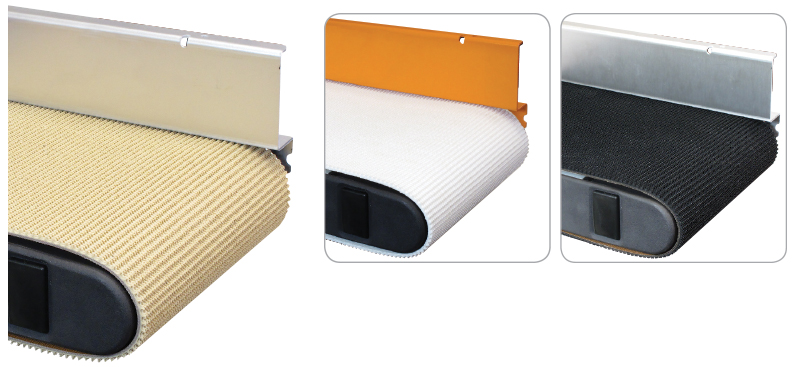

Black PVC Belt:

The black PVC belt has the same specifications as our standard white PVC belt, except the color is black and it is not FDA/USDA approved. The preference is your choice. This belt is available with a ridged texture, and with cleats. For many incline applications this ridged texture belt grips parts, and can be used in the place of a cleated belt.

Gray PVC Belt:

- "Sticky" top, good for incline conveying

- Non-marking

- Contact temperature range: 5°–210°F

- Industrial grade, not FDA approved

White PU Belt:

- Anti-static

- Non-marking

- Contact temperature range: -22°–175°F

- FDA/USDA approved for direct contact of unwrapped foodstuff.

Green PU Belt:

- Anti-static

- Non-marking

- Contact temperature range: -30°–175°F

- FDA/USDA approved for direct contact of unwrapped foodstuff.

- Available with cleats and corrugated side rails

Gray Ridged PVC Belt:

- Anti-static

- Non-marking

- Contact temperature range: 5°–210°F

- Industrial grade, not FDA.

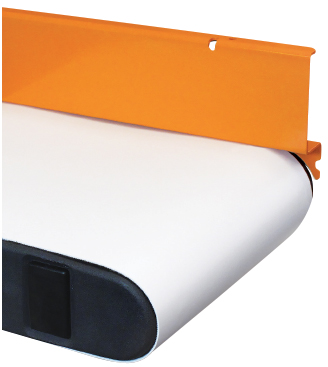

Blue Ridged PVC Belt:

- Anti-static

- Non-marking

- Contact temperature range: 5°–230°F

- FDA/USDA approved for direct contact of unwrapped foodstuff.

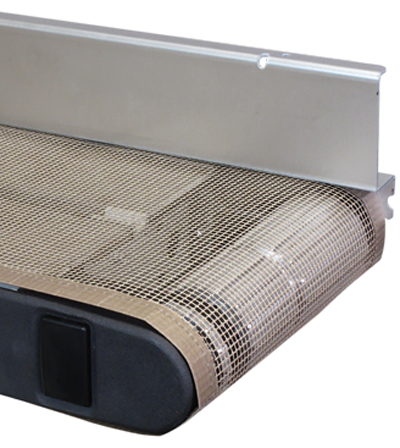

Open Fiberglass High-Temp. Mesh Belt:

Teflon® coated fiberglass material is very resistant and durable to high temperatures. Its open mesh construction allows for air movement through the belt.

- Contact temperature up to 550°F

- FDA/USDA approved for direct contact of unwrapped foodstuff.

3-ply High-Temperature Butyl Belt:

Designed for extreme temperatures this belt is recommended for both high-heat and cooling applications.

- Contact temperature range: -50°–300°F

- FDA/USDA approved for direct contact of unwrapped foodstuff.

Our Rough Top Belt A less expensive alternate to grip parts without using cleats on a belt. A rough top belt creates friction between the belt and the parts being conveyed. A rough top belt may not be suitable for all applications due to the difficulty of maintaining the cleanliness of the belt.

- Flexible, yet stretch and moisture resistant.

- Non-marking

- Contact temperature range: -40°–250°F

- Industrial grade, not FDA

Intralox™ Belting:

Intralox belting is an excellent alternative to PVC belt. These modular plastic belts come in dozens of plastic "grid" or "mesh" surfaces. These interlocked belt surfaces allow for air circulation or water spray between the part and belt. Due to Intralox's unique belting and positive sprocket drive and tracking system, these belts are known to last longer than PVC belts. With Intralox belting there is no mistracking or slippage.

Plastic Mesh Belting:

Plastic conveyor belting (which requires nylon wear strips and a sprocket drive) is easily installed on EMI conveyors. Typical applications include robotic installations and cooling tunnels. Nylon wear strips promote air circulation underneath the belt. Plastic belting, although more expensive, can pay for itself in the long run. If a problem or wear on the belt occurs simply replace a section of the belt.

Silicone Belting:

Silicone belting is another High Temperature belting option, rated up to 500 degrees F. Used for flat belt style only, cannot be cleated.

Flat Wire Belting:

Ideal for moving high-temperature molded parts and providing air cooling as they move. Most any EMI flat or inclined conveyor can include the flat wire belting option. (Which requires Nylon wear strips.) The sprocket drive assures smooth movement. Flat wire belting can be either carbon or stainless steel.

Roller Conveyors:

EMI offers a wide choice of Heavy-duty Roller Conveyors and container handling products for moving large or heavy parts, boxes, containers, totes or pallets.

Flat Top Chain:

Chain Conveyors are designed to move products that a standard roller can't. It's ideal for heavy duty applications and is best suited for unloading or transferring products with unusual characteristics, such as pallets or heavy totes.

Flat Top Belt:

Flat Top Belts are ideal for smooth product flow of individual parts or boxes. Excellent for oriented conveying around bends to avoid obstructions and to service work stations. Available in both Steel Frame and Aluminum Frame.

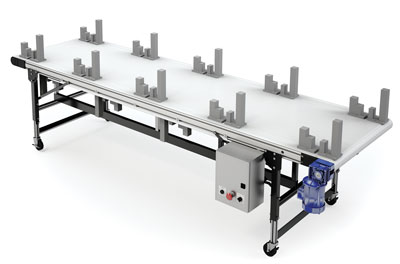

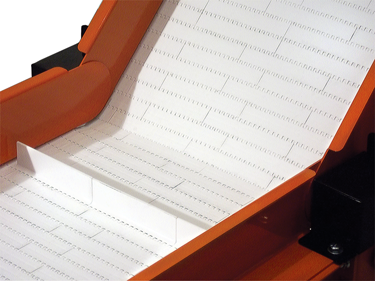

Belting with Nests for Robotic Part Placement

EMI now offers creative solutions when your parts transfers require a specific, repeatable orientation. Product nests, shown here on horizontal belts, can also be customized for inclined applications, to provide effective results beyond what can be achieved using cleats and other methods.

Help keep correct orientation and exact positioning for your additional operations: Contact us to find out if this solution will work for you!