S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

Web Content Viewer

- ${title}

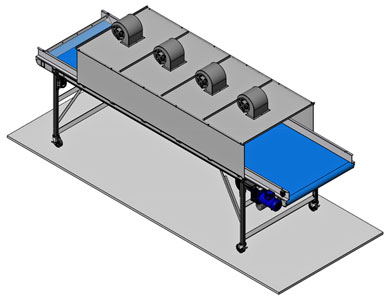

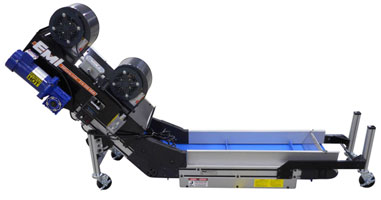

Parts Cooling Conveyors

Post-mold cooling can cut cycle times by quickly cooling hot parts, stabilizing them, and preventing them from deforming. They are an excellent choice for thick walled or blow molded parts applications.

Optional features, such as variable speed drive to adjust the pass-through time or clean air filters, allow them to be custom designed to meet a wide range of application needs. Custom cooling enclosures can be added to almost any EMI conveyor or automatic container filling system. Cooling units can also be retro-fitted in the field on existing EMI conveyors.

Ambient Air Part Cooling

Blowing ambient air over warm parts can be a relatively inexpensive way to help cool warm parts on their way to packing or assembly operations.

Belting Options for Part Cooling

Intralox Belting allows air to circulate freely around and under parts, and is an excellent way to promote cooling.

Chilled Air Part Cooling

Chilled air cooling is an excellent choice when parts need to be thoroughly cooled.

Hybrid / Air Knife Part Cooling

Hybrid options can include a Water spray cooling/ Air knife drying If you need to cool an extrusion or part quickly.

Self Contained Part Cooling

Self-contained cooling units do not need a central chilled water supply and requiring minimal setup.

Water Part Cooling

Water cooling conveyors are an excellent way to cool thick-walled parts as they are being transferred to another conveyor or work station.