Z6_I8001C80MGFH50A5NPQ4Q394M6

Z7_I8001C80MGFH50A5NPQ4Q394U1

S2K Commerce - Shopping Cart

- ${title}

Loading...

Z7_I8001C80MGFH50A5NPQ4Q394U3

S2K Commerce - Products Dropdown

- ${title}

Loading...

Z7_I8001C80MGFH50A5NPQ4Q39410

Web Content Viewer

- ${title}

Loading...

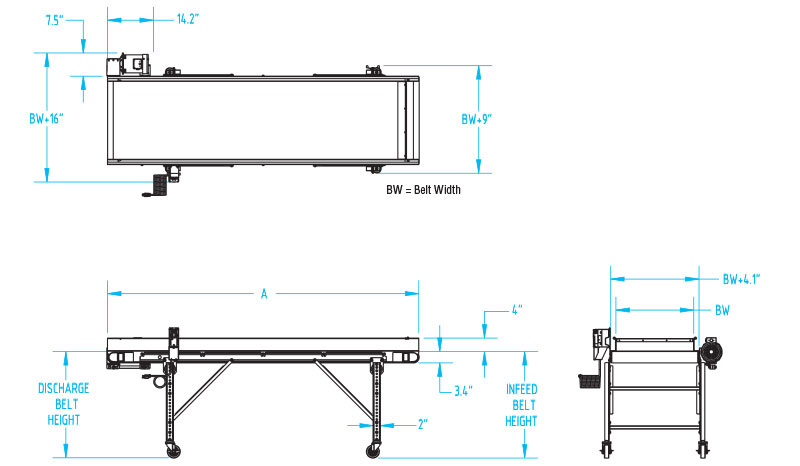

Extruded Aluminum Frame Conveyors, Flat Belt

Standard lengths: 3'–40' at 6" increments.

Standard belt widths: 6", 12", 18", 24", 30", 36"

Available belt widths: 4"-60" at 2" increments.

New EAF Expedited Shipping Program:

Available belt widths: 12", 14", 16", 18", 20", 22" and 24"

Available belt lengths: 4'-15' at 1' increments.

Consult your EMI Representative for a list of available options.

Literature:

Specifications:

- Anodized extruded aluminum frame with side channels that accept standard 3/8" hex head bolts/nuts See Detailed Illustration

- Anodized aluminum side rails 4" high, 90° overlapping the belt 1¼" per side

- New heavy-duty powder-coated steel leg sets with 4" locking swivel castors.

- 110 Volt 1/3hp AC motor with variable speed standard.

- Gear reducer is sealed and permanently lubricated requiring no service

- 4-40 FPM variable speed drive

- Direct drive power transmission

- 100 lb. maximum load

- V-guide belt guidance

- Automatic spring loaded belt tensioning

- Laced, flat PVC belting (blue), FDA approved material

- 210°F belt temperature resistance

- Units up to 20' long are shipped fully assembled

Common Options:

- Extruded Aluminum Conveyor Options

- 2-20 FPM or 7-70 FPM are available at no charge

- Endless belting is available at no charge

- Soft drop zone, to cushion part drop

- Straight side rails or no side rails

- Side rail extensions for part containment

- Lexan™ rail covers

- Chilled air or ambient air blowers for part cooling

- Stainless steel discharge chute

- Alternate belting is available on all EA models. View all the options here.

- Alternate conveyor speed options

- Deionizing blowers to eliminate static electricity and prevent particles from sticking to parts

- Robotic indexing control interface

- Box filling by cycle count or weight

- Reversing for process control

- Alternate motor locations

BW = Belt width