S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

Web Content Viewer

- ${title}

Box & Bag Filling Carousels

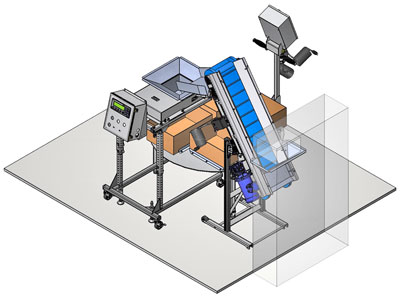

An Automatic Carousel is a versatile, cost-effective way to automatically fill parts into boxes or bags. Compact round shape is great for areas that are often too small for a traditional Inline system, such as the space at the end of the molding machine.

Double the Capacity! A second-level platform can double the capacity of a carousel style box or bag filling system—without using any more floor space than a single-level system.

Standard Operation: The Automatic Carousel can operate on a count signal from the molding machine, a robot or a weigh hopper, and can be programmed to fill many different sizes and shapes of boxes. Note: We can provide an optional counter, which will count machine shots and send an indexing sign.

Specifications:

- Available diameters: 3’, 4’, 5’, 6', and 7'

- Can be programmed to fill up to 24 positions

- Powder coated steel construction - stainless steel available option.

- 1/3 hp, 110/60/1 AC drive

- Shipped with electrical components completely installed and wired

- Control wiring is contained in liquid-tight conduit and connectors

- Swivel locking castors

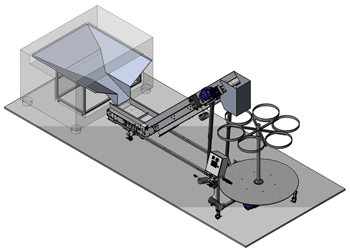

Custom Bag Filling System:  This system combines a Weigh Scale Hopper, which can weigh to within 0.5 grams, and an Automatic Bag Filling Carousel. The system fills almost continuously, stopping only long enough for the parts to drop into the bags. Systems can be configured to fill a wide range of bag sizes and styles.

This system combines a Weigh Scale Hopper, which can weigh to within 0.5 grams, and an Automatic Bag Filling Carousel. The system fills almost continuously, stopping only long enough for the parts to drop into the bags. Systems can be configured to fill a wide range of bag sizes and styles.

How does it work?

- Parts are brought from under the press to a feeding conveyor, which feeds them into the Weigh Scale Hopper

- When the Weigh Scale Hopper reaches its programmed weight, it momentarily stops the feeding conveyor and drops the parts into the 1st bag

- As soon as the parts drop, the weigh hopper flips and the feeding conveyor restarts

- When the correct weight is reached, the Weigh Hopper stops the feeding conveyor and drops the parts into the 2nd bag

- The cycle repeats until all boxes/bags are filled.

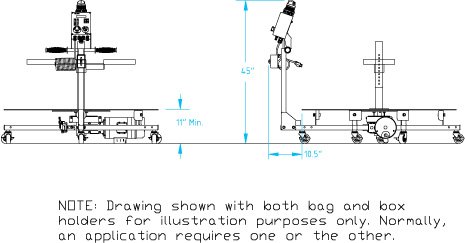

How to Order Bag or Box Holders: To fill bags, an optional bag holder must be ordered.

To position boxes on the turntable, optional box holders must be ordered.

When ordering box or bag holders, please supply the following information:

Box – height, width, length, orientation

Bag – height, width, diameter