S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

Web Content Viewer

- ${title}

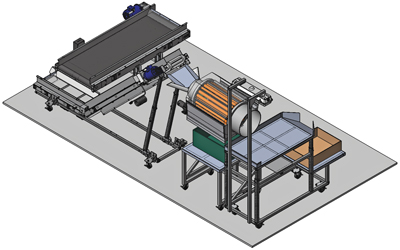

Reversing Conveyors for Quality Control

Automatically removing bad shots is an excellent way to reduce labor costs.

Many of today's molding presses come complete with Process Control Output — a feature that can signal the production of a bad shot. EMI conveyors equipped with a reversing regenerative drive, will automatically reverse and reject the bad shot out the back of the molding press. Shots taken out the back of the press for rejection will not be counted in the box filling system.

The control system incorporates a reversing regenerative DC drive and a NEMA 1 enclosure (incorporating a timer, relays, and a terminal strip). A manual override switch to lock the conveyor in reverse for start-up is available.

How does it work? Upon receipt of a customer-supplied, momentary, bad shot signal (closing our normally open contacts), the conveyor will reverse, convey the bad shot out the back of the press, and then return to the normal conveyor direction. Note: A second bad shot signal will automatically reset the timer.

S-76 Additional Options

- S-76-220VAC Reversing package with 220/60/1 VAC input. The electrical control will be mounted in a 12” tall, 10” wide, 6” deep NEMA 1 enclosure.

- S-76 control package with an AC variable speed drive, using a 110/1/60 VAC input and supplying a 230/3/60 output to the motor. The electrical control will be mounted in a 12" tall, 10" wide, 6" deep NEMA 1 enclosure.

- S-76 with an AC variable speed drive, using a 110/1/60 VAC input and supplying a 230/3/60 output to the motor. The electrical control will be mounted in a 12" tall, 10" wide, 6" deep NEMA 1 enclosure.

- Retro-fit a reversing package to your conveyor.

- Incorporate a metal detector