S2K Commerce - Shopping Cart

- ${title}

S2K Commerce - Products Dropdown

- ${title}

Web Content Viewer

- ${title}

Metal Detecting Flat Bed Conveyors

Cost effective metal detection – Best for applications with metal either on or close to the conveyor belt.

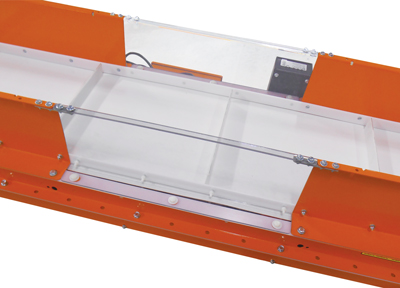

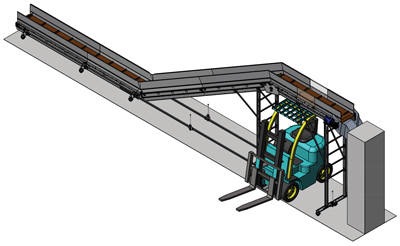

The EMI flat bed, metal detection system is an excellent choice when tramp metal (both ferrous and non-ferrous) is free to fall either onto or close to the conveyor belt. The EMI flat bed metal detector is specifically designed for EMI conveyor systems. Integrated in conveyors feeding granulators the detector will detect ferrous and non-ferrous metals. The detectors consist of two parts. The first part is the compact coil design that is made to fit directly beneath the EMI conveyor belt, scanning material as it passes over the detection field. The second part is a compact, NEMA 4 enclosure that houses the simple to use, single board electronic controls. On this board, basic adjustments can be made to the sensitivity to help tune the system to better suit the application. The sensitivity of the detector is best on the surface but gradually decreases as the distance from the belt surface increases. In most systems where conveyors are being used to feed granulators, the metal parts are loose from the material being conveyed and generally fall to the belt surface. A visual/acoustic alarm and 110VAC 60Hz power conditioner is included in the metal detector package. Note: A "MD" electrical option must be chosen for conveyor control. Cost is considerably less than an aperture-style system.

The system consists a compact coil design flat bed detector which is installed directly beneath the conveyor belt, and a NEMA 4 enclosure which houses simple to use, single board electronic controls.

Sensitivity of the system can be easily adjusted to meet the needs of varying applications.

When metal is detected, the unit will stop the conveyor and signal an operator to remove the metal and reset the system. If automatic quality control is desired, the system can be combined with a parts diverter or reject chute to remove the suspect material.

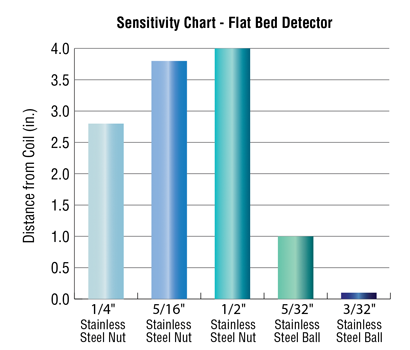

Sensitivity: This graph represents the test results on an EMI flat bed metal detector. In the first test we used various sized Stainless Steel nuts. In the second test we used stainless steel ball bearings. Each bar represents the maximum distance from the coil surface at which the parts could still be detected. Note: The test was performed with stainless steel, because it is more difficult to detect than regular steel.