S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

Web Content Viewer

- ${title}

Cobot Ready Conveyors

EMI has developed a conveyor package to easily integrate with your Universal Robot.

EMI’s Cobot Ready Conveyors are designed to be integrated with your Universal Robot to provide continuous part transfer and are ideal for pick and place, machine tending, and packaging applications. This allows the Cobot and EMI Conveyor to interact without the use of an operator, while increasing productivity and reducing labor intensive jobs in today’s work environment. Choose any of our Conveyor models with either an internal or external drive.

Coupled with EMI’s URCap, any UR can easily control the conveyor’s speed and direction. Set-up is easy, simply connect the included Ethernet cable to your Universal Robot’s control box and install the URCap.

Internal Drive Package Includes: (for EA models only)

- MODBUS communication via EA-PLC – UR with Ethernet connection

- EA-ID (internal drive) with variable speed

- 70 FPM maximum belt speed

- Two photo-eyes (1 at infeed and 1 at discharge end of conveyor)

- Single V-guide blue polyurethane belting

- Power: 110V/5amp

- 50lb Maximum load

- Belt widths 4in to 60in, and Belt Lengths starting at 4ft

External Drive Package Includes:

- MODBUS communication via T-99 Cobot Controller Package with Ethernet connection

- External variable frequency drive

- 20, 40, or 80 FPM belt speed

- Two photo-eyes (1 at infeed and 1 at discharge end of conveyor)

- Power: 110V/5amp

- Maximum load depends on model of conveyor

- Belt widths vary by conveyor model and Belt Lengths starting at 4ft

Included URCap Features:

To install, simply insert the included USB drive to the UR teach pendant.

- MODBUS communication via Ethernet cable

- Simple UR teach pendant interface for easy programming

- Compact touch screen speed control

- Variable speed control

- Directional control

- Detect workpiece presence

- User Manual

Download Brochures / Datasheets

Integrating multiple cobot assisted conveyors with your Collaborative Robot can be used for simplified box-filling systems.

EMI URCap allows for easy programming and use when integrated with your UR. Using a Doosan, Kuka, Fanuc, or other Collaborative Robot? Contact us to discuss!

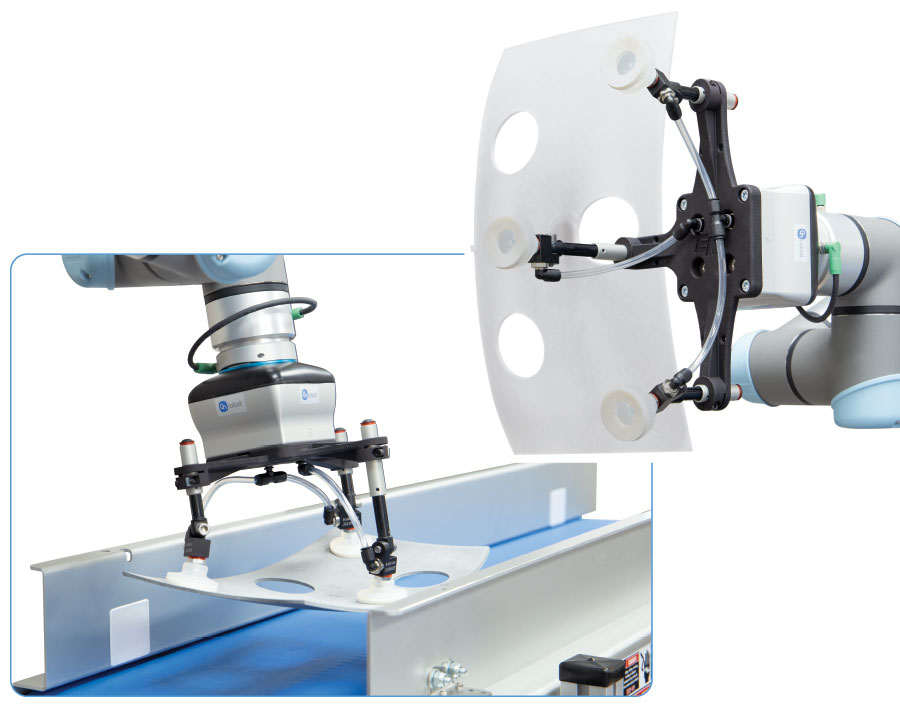

Combining a traditional EOAT with a Cobot EOAT and Cobot Ready Conveyor

EMI’s plate EOAT removes the part from the injection mold, hands it off to the Cobot end effector customized by our Engineers, and delivers the workpiece to a Cobot-Ready Conveyor. EMI helped automate this real world application in a customer facility.

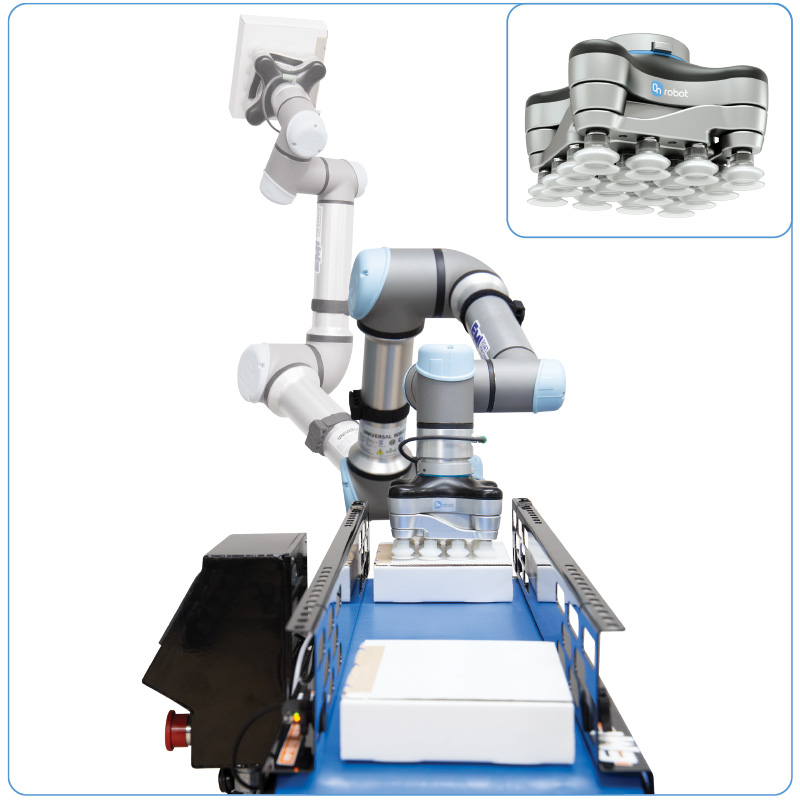

OnRobot VGC10 with Custom 3D Printed EOAT and Cobot Ready Conveyor by EMI With a 33lbs payload, dual vacuum channels, built-in Quick Changer and Electric Vacuum Generator, the VGC10 is the next level of Vacuum EOAT for Cobots. Coupled with EMI’s Cobot Conveyor, EOAT framing, vacuum cups selection, 3D print capabilities and Engineering services, OnRobot’s VGC10 is a powerful Vacuum EOAT solution.

VG10 Vacuum Gripper shown below in its most compact form working with an EMI Cobot Ready Conveyor is perfect for packaging applications.

Cobot Ready Compatible Conveyors:

Internal Motor: EMI’s Extruded Aluminum Frame Conveyors Deliver a Sturdy, Lightweight Construction.

Low profile with an internal drive, this minimize interference when your operators and robots have to work closely around the conveyor.

Find additional specifications on our EAF - Flat Belt Extruded Aluminum Belt Conveyor here.

External Motor: Choose any EMI Conveyor.

Choose from Steel or aluminum frame. The maximum load, belt width, and belt length varies per model.

Find additional specifications on our Standard Conveyor Models here.

Robotic Indexing Control Options:

EMI's indexing controls make it easy to interface a parts take conveyor with your robot.

Depending on your choice of Internal or External drives, your 'Cobot Ready Conveyor' comes with our Compact PLC Indexing Control (for Internal drive) or the T-99 Cobot Controller Package

Find additional specifications on our Robotic Indexing Control Conveyor Systems here.

Standard Extruded Aluminum models: Motor and Drive Mounted Within the Conveyor Frame.

Our Internal Drive Option (EA-ID) reduces conveyor width by 7-3/4" compared to the standard motor and drive.

Easily automate tasks to increase productivity!

Whether you are automating your process using multiple cobot assisted conveyors or multiple collaborative robots, EMI can help develop an ideal solution. Find out more about our Adjustable height and Fixed height Cobot Stands. Click images below for a detailed view.