S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

S2K Commerce - Order Entry

- ${title}

OnRobot Vacuum Grippers for Cobots

OnRobot's Electric Vacuum Grippers are ideal for Molded Plastic Parts as it can use independent vacuum channels to handle separate mold cavities.

Both the VG10 and VGC10 feature two independent LH/RH air channels for dual gripping is helpful for handling plastic molded parts. Also available from EMI, the OnRobot Gecko Grippers come with either as single pads of Ø35mm, Ø60mm and Ø75mm or in the original configuration which has 4x pads, part sensing and a part release mechanism.

Shown to the right, the OnRobot VGC10 Electric Vacuum Generator is the next level of Vacuum EOAT for Cobots. Versatile and compact, this powerful unit is compatible with EMI’s EOAT Framing, large vacuum cup selection, 3D printing for EOAT and backed by our Engineering services. Some of the features include: Electric vacuum generator with dual vacuum channels, built-in quick changer, and a 33lbs payload. No compressed air required.

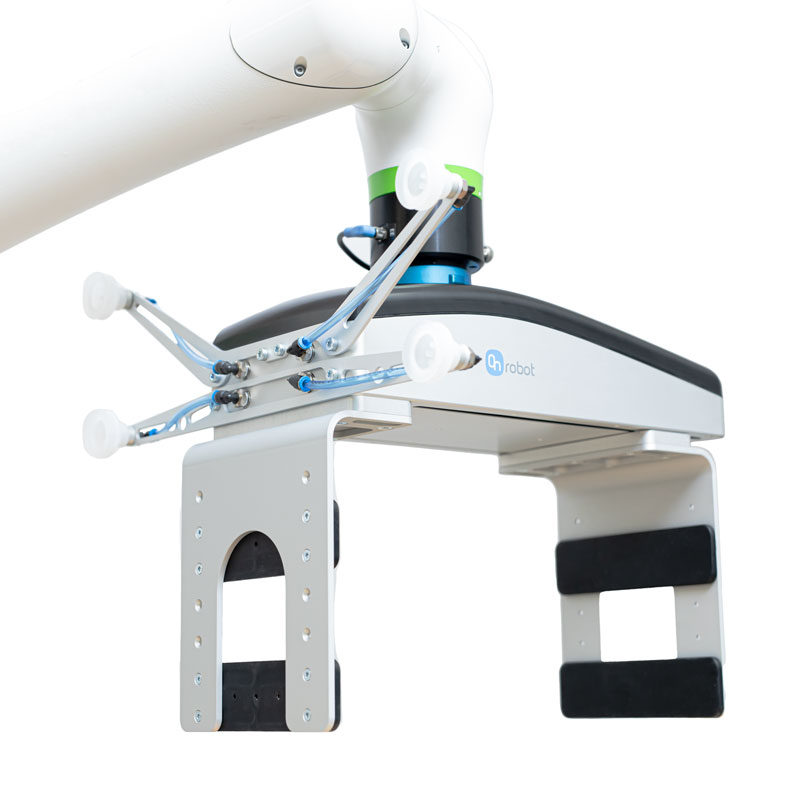

With 16 vacuum ports, included fittings, plugs, swiveling arms that give you up to a 400mm footprint, built-in Quick Changer, the VG10 is a next generation Vacuum EOAT that enables you to start producing with minimal setup time and accessories. Additionally, EMI provides many compatible vacuum cups.

See Q#8211 if you need a customizable Vacuum EOAT using EMI’s EOAT framing, vacuum cups, 3D printing or laser cut plates.

- Seamless integration with the robot of your choice.

- Weight: 1.62kg / 3.57 lbs

- Integrated software.

- No external air supply required.

- Built-in electric vacuum generator.

- May require a Compute Box with some Robot models.

| Technical data | |

|---|---|

| Vacuum | 5% Vacuum — 80% Vacuum (1.5Hg — 24Hg) |

| Max. Air flow | 12 Nl/min (0.42 SCFM) |

| Arms adjustment | 0° — 270° |

| Arm holding torque | 6Nm |

| Maximum Payload | 15kg (33lb) |

| Gripping time | 0.35 seconds |

| Releasing time | 0.20 seconds |

| Operating Conditions | |

|---|---|

| Power supply | 20.4V — 28.8V |

| Current consumption | 50mA — 1500mA |

| Operating temperature | 32° — 131°F |

Smaller than the Q# 8210 VG10, the VGC10 can fit into tight environments to extend your automation possibilities. And at half the weight of the VG10 but with the same payload, the VGC10 can lift small, odd-shaped, and heavy objects even with a smaller robot arm. The VGC10 features two independently controlled air channels that allow it to act as a dual gripper with pick-up and release in the same action, further increasing efficiency and reducing cycle time. With no compressor or air supply needed, this compact electrical gripper is easy to move, and simple programming makes it quick and easy to redeploy for greater production flexibility.

- Built-in electric vacuum generator.

- Weight: 0.814kg / 1.79 lbs

- Flexible electric vacuum gripper with unlimited customization fits all your application needs.

- Compact, lightweight gripper is perfect for tight spaces but with plenty of power for objects up to 15kg.

- No external air supply needed.

- Integrated software.

- May require a Compute Box with some Robot models.

| Technical data | |

|---|---|

| Vacuum | 5% — 80% Vacuum (1.5Hg — 24Hg) |

| Air flow | 12 Nl/min (0.42 SCFM) |

| Max. Payload with default attachments* | 6kg (13.2lbs) |

| Max. Payload with custom attachments* | 15kg (33.1lbs) |

| Gripping time | 0.35 seconds |

| Releasing time | 0.20 seconds |

* When using three 40mm cups (more info in the Payload tab to the right). Number of cups needed for non-porous materials varies depending on payload and vacuum.

| Operating Conditions | |

|---|---|

| Power supply | 20.4V — 28.8V |

| Current consumption | 50mA — 1500mA |

| Operating temperature | 32° — 122°F |

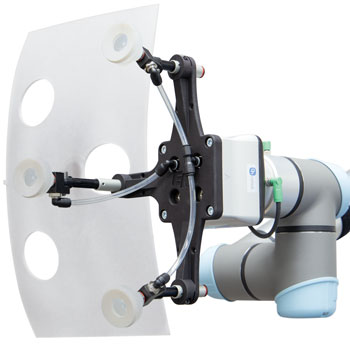

The Gecko Single Pad (SP) Gripper brings the innovative Gecko adhesive gripper technology to small-footprint applications that were previously impossible to automate. The gecko-inspired adhesive technology offers precise, no-mark gripping, even for perforated items such as circuit boards or for shiny surfaces, without the cleaning process. Named after their payload in kilos, the three different Gecko Single Pad grippers (SP1, SP3 and SP5) work with leading small robots and cobots. The compact, single-pad design allows easy workpiece accessibility, even in tight spaces. With no electronics or air supply needed, the Gecko SP is a cost-effective, true plug-and-play solution. Seamless integration with the robot of your choice.

The Gecko Single Pad (SP) Gripper brings the innovative Gecko adhesive gripper technology to small-footprint applications that were previously impossible to automate. The gecko-inspired adhesive technology offers precise, no-mark gripping, even for perforated items such as circuit boards or for shiny surfaces, without the cleaning process. Named after their payload in kilos, the three different Gecko Single Pad grippers (SP1, SP3 and SP5) work with leading small robots and cobots. The compact, single-pad design allows easy workpiece accessibility, even in tight spaces. With no electronics or air supply needed, the Gecko SP is a cost-effective, true plug-and-play solution. Seamless integration with the robot of your choice.

The Gecko Single Pad (SP) Gripper brings the innovative Gecko adhesive gripper technology to small-footprint applications that were previously impossible to automate. The gecko-inspired adhesive technology offers precise, no-mark gripping, even for perforated items such as circuit boards or for shiny surfaces, without the cleaning process. Named after their payload in kilos, the three different Gecko Single Pad grippers (SP1, SP3 and SP5) work with leading small robots and cobots. The compact, single-pad design allows easy workpiece accessibility, even in tight spaces. With no electronics or air supply needed, the Gecko SP is a cost-effective, true plug-and-play solution. Seamless integration with the robot of your choice.

- Built-in intelligence and multichannel functionality ensure failsafe, flexible operation.

- Complete out-of-the-box vacuum gripper offers fast, easy deployment with any leading robot.

- Powerful, flexible gripper is ideal for porous and non-porous surfaces.

- Dimensions: 250mm x 170mm, 92mm tall.

- Sixteen ∅40mm Vacuum cups are included with a total 450mm footprint. Many other cup options are available.

VGP 20 Specifications

| Technical data | Min | Typical | Max |

|---|---|---|---|

| Vacuum | 5% Vacuum / 1.5Hg | - | 60% Vacuum / 17.95Hg |

| Air flow (each Channel) | 0 Nl/min | - | 12 Nl/min |

| Payload with default attachments* | - | - | 20kg / 44.09lb |

| Noise level | - | 67dB(A) | 71dB(A) |

| Gripping time** | - | 0.25 sec | - |

| Releasing time** | - | 0.40 seconds | - |

*Cardboard is recommended to 10kg. Other conditions apply, see tab below.

** The gripping time can be shortened with smaller or less suction cups. The release time depends on the payload. With high payload, you can achieve fast release time.

| Operating Conditions | Min | Typical | Max |

|---|---|---|---|

| Power supply | 20.4V | 24V | 28.8V |

| Current consumption | 50mA | 2500mA | 4500mA |

| Operating temperature | 0°C / 32°F | - | 50°C / 122°F |

| Calculated MTBF (operating life) | 25,000 hours | - | - |

- Highly versatile palletizing gripper with wide stroke and customizable arms handles heavy or open boxes, shelf-ready products and other containers that can’t be gripped with vacuum

- Integrated vacuum gripper handles slip sheets without changing the gripper or requiring other handling method

- Off-the-shelf gripper saves significant engineering effort and shortens deployment time

- Electric gripper offers fast out-of-the-box deployment without the complexity and costs of external air supply

- Gripper will hold workpiece in case of powerloss

- Integrated electric BLDC motor included

- Vacuum unit includes integrated 50μm field replaceable dust filters

- IP 54 Classification

- Base unit weight with standard fingers and pads: 5.07kg (11.18 lb)

- Base unit weight with standard fingers, pads and all vacuum equipment: 5.34kg (11.77 lb)

| Finger Grip Properties | |

|---|---|

| Max. Payload | 20kg (44.1lbs) |

| Total Stroke | 260mm (10.24in) |

| Grip width range (1) | 170mm — 430mm (6.69 — 16.93in) |

| Gripping repeatability | +/- 0.5mm (0.0197in) |

| Gripping force (2) | 80 — 400N |

| Gripping force tolerance | +/- 30N |

| Gripping speed (3) | 16 — 180 mm/s |

| Gripping time (including brake actuation) | 600ms |

| Noise level (finger gripper) (4) | 58 [dB(A)]Leq 63[dB(A)]Max |

| Noise level (vacuum gripper) (4) | 72 [dB(A)]Leq 74[dB(A)]Max |

(1)When pads are mounted, the minimum value is 158mm and the maximum value is 418mm. (2)See Force vs Current Graph in the next tab. (3)At 6mm stroke and 150N. The typical value is 900ms at 20mm and 200N. (4)The noise level of the 2FGP20 depends on whether the finger or vacuum gripping part is used. Vacuum gripping noise depends on the set vacuum level and whether an object is picked up or not. Higher speed and stroke increase the noise. The noise level also depends on the surroundings and other equipment.

| Vacuum Grip Properties | |

|---|---|

| Vacuum | 5 — 60% Vacuum (-0.05 — -0.607 Bar)(1.5 — 17.95 inHg) |

| Air flow | 0 — 12 L/min |

| Max. payload (with delivered attachments) | 2.5 kg (5.51 lb) |

| Vacuum cups | 1 — 4 |

| Typical gripping time (measured with vacuum target 40%) | 0.25 s |

| Typical release time | 0.4 s |

| Operating Conditions | |

|---|---|

| Power Supply | 20 — 25 V |

| Current consumption | 2000 mA |

| Operating temperature | 5 —50 °C (41 — 122 °F) |

| Relative humidity (non-condensing) | 0 — 95% |