S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}

S2K Commerce - Order Entry

- ${title}

Custom EOAT for Cobots from EMI

EMI EOAT Engineering is available to help develop your next Custom Cobot Application. If you need a single vacuum cup attached to your cobot, or a two-sided EOAT for ultrasonic welding EMI has the support, inventory and experience to provide a solution that is cost effective yet durable and tailored to your application needs.

Below you can see some custom designs that have been developed by EMI from the ground up: Vacuum end effectors using OnRobot’s electric vacuum generators, dual gripper setups for machine tending, two-sided insert-loading EOAT for plastic injection molding, and pick-and-place via vacuum or soft touch grippers.

Contact our EOAT Engineers to discuss your next project; whether you’re getting the first cobot in-house, or if they’re being implemented across your facility.

Watch our EOAT for Cobots video and follow us on YouTube for other videos!

EMI has the largest offering of in-stock components and solutions for End of Arm Tooling, supported by a team of experienced engineers and sales personnel. View the video and subscribe to our YouTube channel!

3D Printed Vacuum EOAT and Manual Quick Changer

3D Printed Vacuum EOAT are the perfect approach for Cobot applications that require higher payload for part handling. Using a Gimatic QC75 Tool Changer provides easy pneumatic and electric circuit coupling.

The 3D printed frame is designed to order and can incorporate suspensions, vacuum posts or direct-mounted vacuum cups. EMI offers the largest in-stock selection of vacuum cups.

Find our more about the Quick Changers for Cobots , 3D Printed EOAT , and the Vacuum Cups we offer.

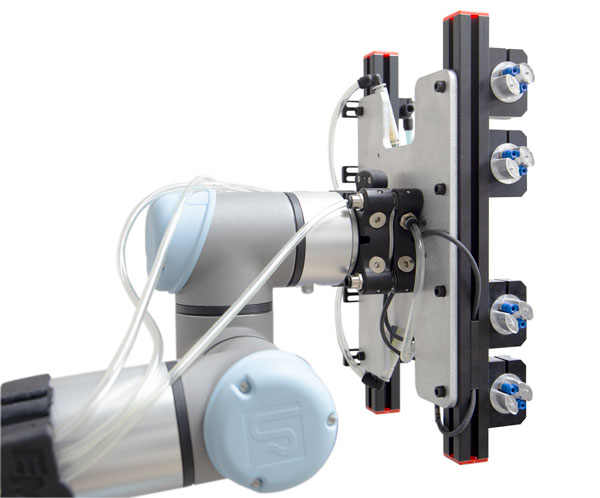

EMI and OnRobot

EMI stocks and supports OnRobot's line of end effectors including the VGC10, an electric vacuum generator. No compressed air is needed! Compatible with 3D printed, extruded aluminum and laser cut plate EOATs using EMI’s extensive offering of components and Engineering support.

Visit our Cobot Mounting section to see plates that are compatible with the VGC10 and extruded aluminum profile EOAT framing. You can also learn more about 3D printing an EOAT for your existing VGC10. Learn more.

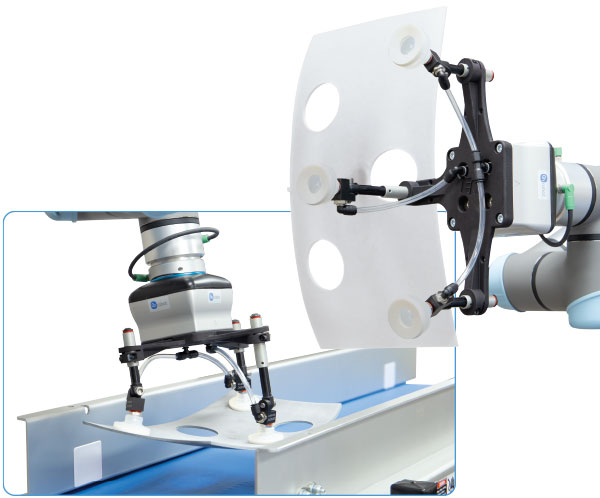

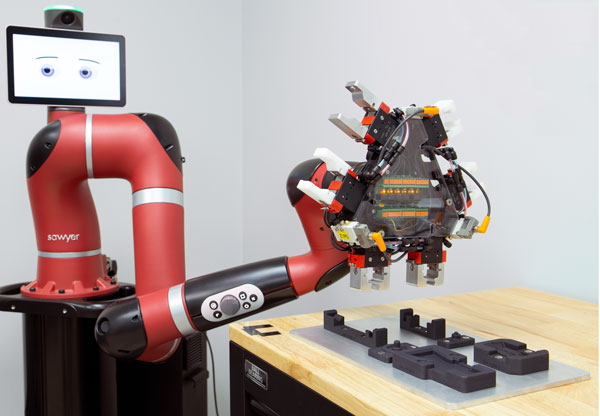

2-Sided Vacuum Eoat With Self-Contained Part Rotation

This custom end-effector uses independent vacuum circuits on opposite sides to grip 2 different parts out of an Injection Molding Machine, for placement into a secondary assembly process. Before placement, self-contained 180° rotary action is required for proper reorientation of a part. Once the secondary assembly is complete, the EOAT removes the final assembly.

Onboard pneumatic valves control air flow to cartridge vacuum generators, and part confirmation is achieved through vacuum monitor switches. All I/O operates through ClickSmart connectors at Sawyer’s wrist.

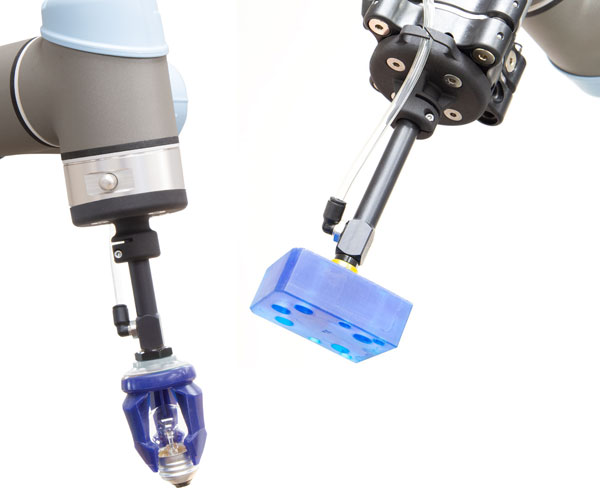

Custom Pick and Place Solutions

EMI designed 3D Printed Cobot Mono Clamps are lightweight, cost effective and easy to use. Simply mount to your Cobot with an existing ISO-9409-1-50-4-M6 or to our Cobot Quick Changer with the included hardware and spacer. Available in 10mm, 14mm, 20mm, 30mm clampable diameters and compatible with a wide variety of components from our EOAT catalog.

Find our more about our Cobot Mono-Clamps.

Find our more about the PIAB piSOFTGRIP gripper.

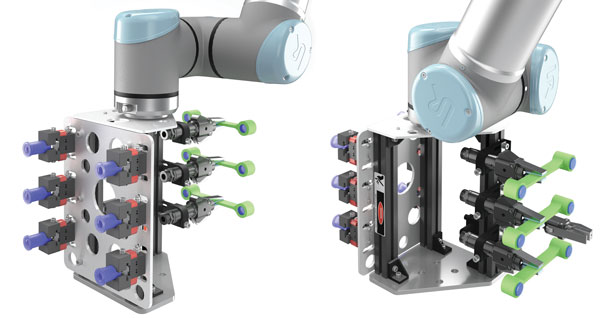

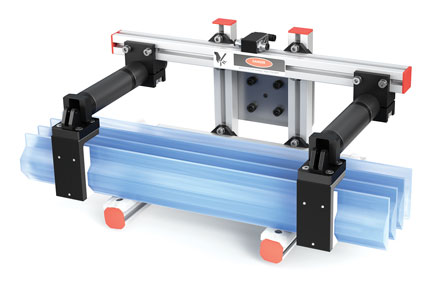

Two-Gripper EOAT with Quick Changer

A custom EOAT to handle a singular part using two pneumatically-powered grippers for added security and positional consistency. A V-groove nest assists in guiding the EOAT into position during robot setup and locating the part during pick and place operations. On-gripper inductive sensors provide part confirmation to the robot through electrical connectors on the quick changer, while pneumatic pass-through in the quick changer automatically connects the robot-provided air to operate the grippers.

Find our more about the MGX High-Precision Grippers.

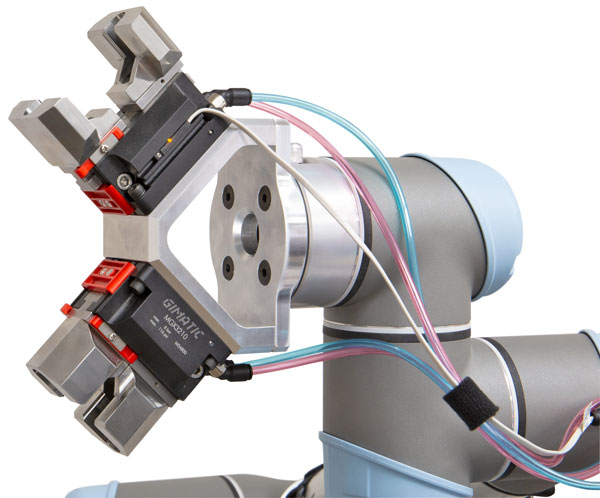

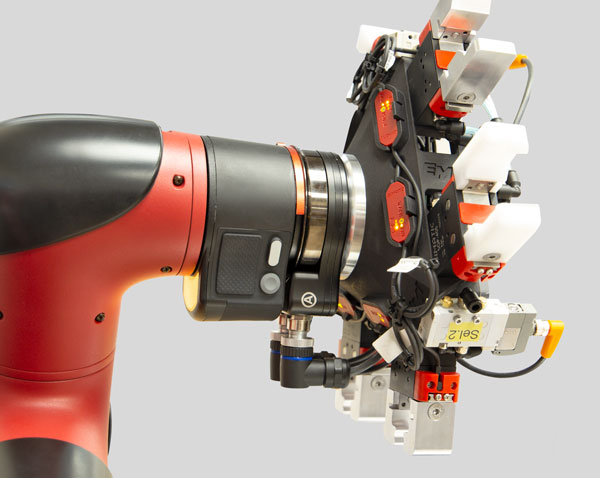

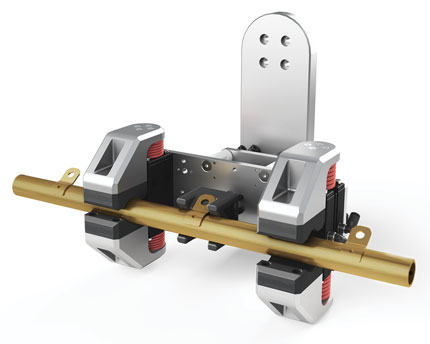

Dual MGX Parallel Grippers

Featuring dual Gimatic MGX parallel grippers, machined fingers and a custom mount, this is a solution that caters to heavy duty machine tending applications at an affordable price.

EMI’s in-house machining capabilities in aluminum, tool steel, and stainless steel simplify the design process and delivery.

Find our more about our MGX, High precision, High force grippers.

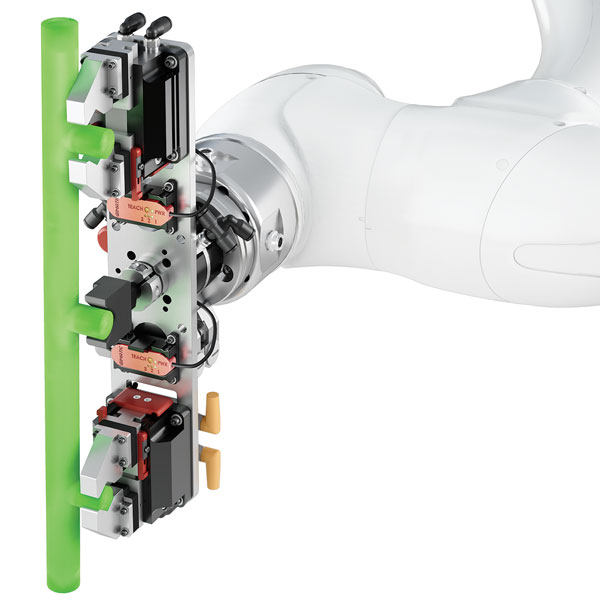

Insert Load Application

This is a traditional insert load application for plastic injection molding. The cobot uses a custom 2-sided EOAT to accurately place metal inserts into the mold, then picks the finished parts. Insert-Load side of the EOAT with part detection. Part-picking side of the EOAT with soft touch angular grippers.

Learn more about EMI’s EOAT Design Assistance.

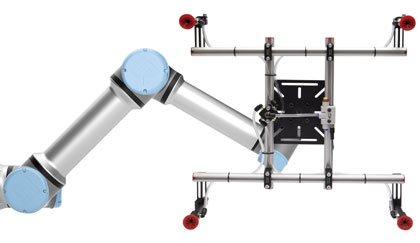

Custom 3D Printed EOAT and Cobot Ready Conveyor by EMI

EMI’s Cobot Ready Conveyors are designed to be integrated with your Universal Robot to provide continuous part transfer and are ideal for pick and place, machine tending, and packaging applications.

Find our more about our 3D Printing service.

Find our more about our Cobot Ready Conveyors.

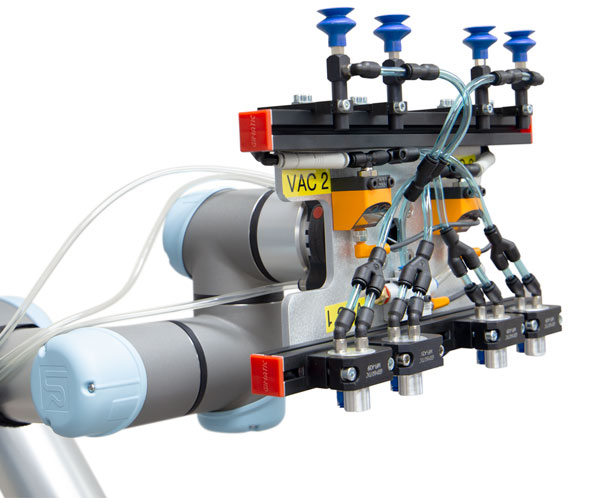

Custom Insert Loading Application

This custom End of Arm Tooling performs insert loading and part picking for an injection molding application. Using in-line vacuum generators and vacuum monitor sensors, the EOAT places inserts in the mold and picks finished parts, providing confirmation signals for both operations.

Find our more about our QC-75 for Cobot Applications.

Custom Cobot Application with QC75

The Gimatic QC-75, a Cobot-specific quick changer, provides a quick disconnect for the EOAT and all of its electrical and pneumatic connections. The QC-75 also provides a confirmation signal that the EOAT is properly mounted and locked onto the Cobot. Mount this quick changer to your Cobot with hole pattern ISO-9409-1-50-4-M6.

Custom 3D Printed EOAT

Our 3D-printed material provides a durable, yet very lightweight mounting interface for vacuum cups, and suspensions in this multi-cavity Cobot application.

Nine parts with a porous surface are gripped with silicone foam vacuum cups that adhere and provide an adequate holding force in order to transfer the workpieces from a conveyor to their intended application.

Learn more about our 3D Printed Vacuum EOAT for Cobots.

Custom 3D Printed EOAT

Measuring approximately 20in. X 17.5in, this sectional 3D-printed frame is comprised of 5 pieces that are assembled together. It features low-tolerance internal nesting, hardware, and pass-throughs for tubing. Three vacuum generators convert a supplied compressed air line to power the nine vacuum cups, split into groups of three.

Find out more about our 3D Printing for EOAT service.

Custom Bag Filling Application

This custom End of Arm Tooling automates a bag filling operation, performing three part pick sequences and one loading sequence to fill a bag with six unique parts. The structure is a 3D-Printed housing that neatly contains the electrical board and wiring for the part confirmation sensors, as well as the outputs that control the solenoid valves.

3D Printed Teachable Sensor Housing

Additionally, the 3D Printed housing provides clip-in attachments for the sensors’ Teach Pendants, which can be easily programmed without making any mechanical or electrical adjustments to the tooling. The Lexan cover provides a convenient visual confirmation of part confirmation signals for easy troubleshooting.

Find out more about our Teachable PRO Sensors.

Unload Several Parts Simultaneously

This EOAT has a modular design for easy adjustments. The OFR Finger Grippers with 95° angular motion trap parts and then deposit them into containers.

Find out more about our OFR Finger Grippers.

Plan Ahead with 2-Piece Finger Tips

Two Gimatic SX parallel grippers with custom radial-groove finger tips engage while the nest secures parts. The two-piece jaw design allows for finger tip change-out if the application changes. The offset mounting plate was designed for Fanuc robots and can be mounted to a quick changer for easy tool change.

Find out more about our SX Parallel Grippers.

Have a specialty application that requires a custom EOAT? Contact us to discuss!

EMI is the EOAT Specialist

- With over 12,000 custom EOAT projects completed, our 20 dedicated EOAT Engineers are on staff ready to answer YOUR EOAT questions about YOUR EOAT project.

- Find our Machine Tending Datasheet. This will assist our Engineers with your application.

- Experienced in-house engineering and manufacturing of gripper fingers, interface plates and vacuum framing.

- In-stock inventory in Ohio ready to ship the same day.

- Upfront, online pricing with E-commerce ease of buying.

- Local sales support throughout the US, CAN, and MEX by EMI employees.

Standard In-Stock EMI Cobot Gripper Kits

The Kit is easy to install and operate. Connect your 6mm compressed air line, a 4-wire cable to the controller box, install our URCap, and your Pneumatic 3D-V Vacuum Kit is ready to expand the capabilities of your Collaborative Industrial Robot.

Features:

- Certified by Universal Robots

- Compatible with OnRobot VGC10

- Fully Customizable: (1–16) vacuum cups with variable spacing.

- Select the ideal vacuum cup for your application: High Temperature, Non-Marking Hithane, Dual Durometer for textured parts, Anti-Static, and many other options. Check out our Vacuum Cup Section.

- Integrated Vacuum Generator with a monitoring switch for part confirmation.

- Internal manifold inside the core of the frame to reduce hazards from tubing.

- Lightweight 3D printed frame made out of durable nylon.

Smaller than the Q# 8210 VG10, the VGC10 can fit into tight environments to extend your automation possibilities. And at half the weight of the VG10 but with the same payload, the VGC10 can lift small, odd-shaped, and heavy objects even with a smaller robot arm. The VGC10 features two independently controlled air channels that allow it to act as a dual gripper with pick-up and release in the same action, further increasing efficiency and reducing cycle time. With no compressor or air supply needed, this compact electrical gripper is easy to move, and simple programming makes it quick and easy to redeploy for greater production flexibility.

- Built-in electric vacuum generator.

- Weight: 0.814kg / 1.79 lbs

- Flexible electric vacuum gripper with unlimited customization fits all your application needs.

- Compact, lightweight gripper is perfect for tight spaces but with plenty of power for objects up to 15kg.

- No external air supply needed.

- Integrated software.

- May require a Compute Box with some Robot models.

| Technical data | |

|---|---|

| Vacuum | 5% — 80% Vacuum (1.5Hg — 24Hg) |

| Air flow | 12 Nl/min (0.42 SCFM) |

| Max. Payload with default attachments* | 6kg (13.2lbs) |

| Max. Payload with custom attachments* | 15kg (33.1lbs) |

| Gripping time | 0.35 seconds |

| Releasing time | 0.20 seconds |

* When using three 40mm cups (more info in the Payload tab to the right). Number of cups needed for non-porous materials varies depending on payload and vacuum.

| Operating Conditions | |

|---|---|

| Power supply | 20.4V — 28.8V |

| Current consumption | 50mA — 1500mA |

| Operating temperature | 32° — 122°F |