Z7_I8001C80MGFH50A5NPQ4Q39UE4

S2K Commerce - Shopping Cart

- ${title}

Loading...

Z7_I8001C80MGFH50A5NPQ4Q39UE6

S2K Commerce - Products Dropdown

- ${title}

Loading...

Z7_I8001C80MGFH50A5NPQ4Q39UE5

Web Content Viewer

- ${title}

Loading...

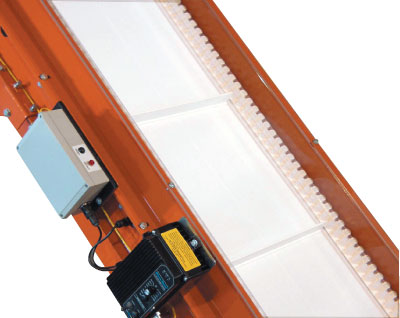

Metal Detecting Conveyor Options

Metal Detecting conveyors are ideal for feeding granulators when tramp metal or inserts may be mixed in with the scrap.

Both conveyors feature a non-metallic, center section made of fiberglass and reinforced with trusses, to support the metal detector's weight. Depending upon the control system, detection of metal either stops the conveyor until it is reset, or reverses the belt until the scrap is removed.

EMI will design your metal detecting conveyor according to specific application needs. The type of metal detection used will depend upon a number of factors including:

- What are the dimensions of the largest part being fed into the grinder?

- How much material will you be feeding into the grinder at a time?

- How large is the metal you wish to detect (i.e. pliers, inserts, staples etc.)?

- Is the metal that is detected going to be transported to a container, or will it be removed by hand?

Aperture Style Metal Detecting

Aperture metal detection is a highly effective means of protecting almost any type of machinery that may be damaged by metal parts or pieces.

Flat Bed Style Metal Detecting

Cost effective metal detection – Best for applications with metal either on or close to the conveyor belt.