S2K Commerce - Shopping Cart

- ${title}

S2K Commerce - Products Dropdown

- ${title}

Web Content Viewer

- ${title}

Clean Room Conveyors

Minimizing grease, oil, dirt and debris in a sanitary environment can be one the biggest challenges for medical molders. Our ACR line of clean room-friendly conveyors offers medical molders a high-quality, economical solution for automating their clean room facilities.

Main Features:

- Aluminum framing, stainless steel guarding and legs resist corrosion and eliminate paint-chip contamination

- A USDA/FDA approved belt

- An open-construction slide bed with UHMW contact strips eliminates places where abrasive debris can collect

- 150 lbs. maximum load

- Leg Sets and Castors included (adjustable up to 34" belt height)

- Direct Drive motor replaces leak-prone, chain-driven systems

- 1/3 hp 110V input AC Variable Speed Drive

- 4-40 FPM Variable Speed

- Sealed bearings reduce the possibility of lubricant leaks

Options:

- Stainless steel framing

- Sealed belt edges to minimize dust from belt fraying

- Linear actuated vertical Lexan door (shown)

- Non-fraying Intralox plastic belting eliminates friction contamination and is fast and easy to clean

- Wash-down compliant electrics

- USDA/FDA approved Delrin® rail lining to keep parts from touching the metal side rails

- Maintenance-free, grease-lubricated gearbox to prevent leak contamination

- Deionizing blowers to eliminate static electricity and prevent particulates from sticking to molded parts

- Catch trays to prevent particulates from escaping into the environment

Specifications:

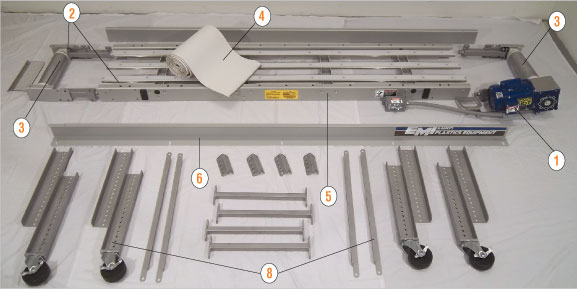

1. Drive Package: Includes a 1/3 hp 110V input AC TEFC motor with a 4-40 FPM variable speed controller. The gear reducer is sealed and permanently lubricated requiring no service. Power transmission is provided via direct drive configuration. 15' of SJ cord with a standard three-prong plug is pre-wired to the starter. Control wiring is contained in liquid-tight conduit and connectors. Drive packages 3'–30' long have 150 lb. maximum load.

2. Belt Guidance: True Track Belt Guidance System comes standard on 3'–30' long conveyors. Using a Double V-guide slot in the frame, 1/4" wall crowned pulleys, and bonded Double V-guide belting, “True Track” minimizes belt run off and reduces belt tracking maintenance.

3. Pulleys: To ensure long lived operation, 3.5” diameter crowned pulleys incorporate 1" diameter shafts, self aligning sealed ball bearings with eccentric locking collars, telescopic take-up adjustment, position locking nuts, and Zerk grease fittings.

4. Belting: Our easy to clean, FDA approved, white, PVC belting with staple-type belt lacing (which prevents lacing pullout and splice failure), makes belt maintenance quick and easy. Inclined conveyors have a bottom cleat support plate and bonded flexible cleats that have no bolts or rivets that may tear out.

5. Frame: 1/8" anodized sheet aluminum for greater portability, built to withstand heavy-duty industrial wear.

6. Rails: The standard 1/8” anodized aluminum 4" rails overlap the belt to ensure molded pieces do not get pinched, damaged, or lost between the rail and belt. To keep your molded parts contained on the infeed end of the conveyor, we include an infeed-end backpiece.

7. Shipment: Generally conveyors 3'–10' are shipped fully assembled, pre-wired, tested, and ready to run (legs must be attached). Conveyors 11' and over are shipped partially assembled to minimize shipping damage. Some frame and belt assembly is required; drive packages and system panels are pre-assembled and tested. For your convenience, arrangements can be made for longer conveyors to be shipped assembled.

8. Leg Sets: Quick adjusting leg sets and locking swivel castors are included as standard on all Clean Room conveyors. Belt height must be specified.