Web Content Viewer

- ${title}

EMI Laser-Cut Flat Plate Tooling Case Study

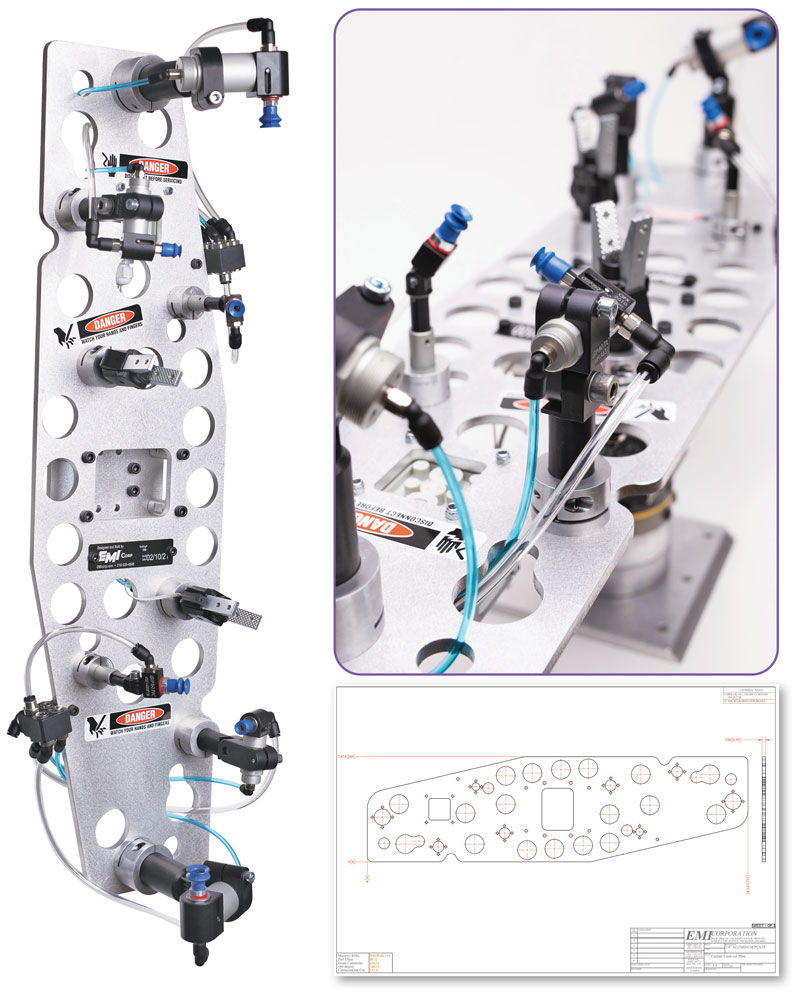

Laser-Cut Plate EOAT from EMI –

A Lightweight and Cost Effective Alternative to Profile EOAT

EMI's laser-cutting machinery allows us to make plate-based EOAT fast, accurate, and at a low cost.

Typical plate-based EOAT is laser cut from 1/8”, 3/16”, or 1/4” aluminum or 12-gauge stainless steel—standard materials in our inventory. Below you can see examples of material cutouts are used for weight reduction and how thinner, lighter material can be strengthened by incorporating reinforcing bends.

Call or email our EOAT engineering department to discuss custom eoat plates for your application.

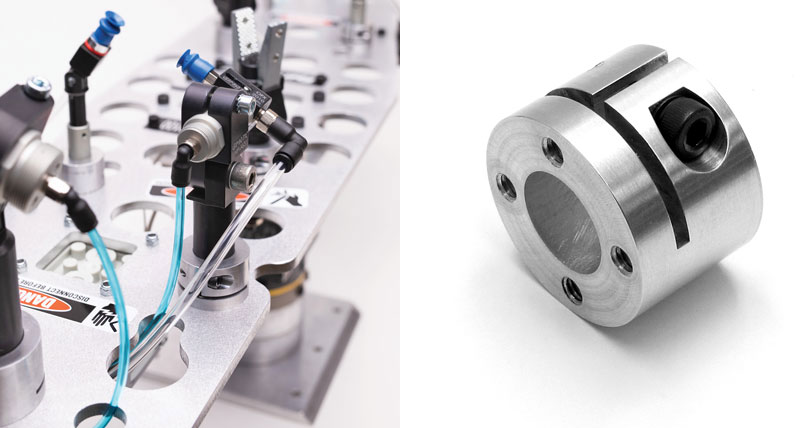

Keep Tubing and Wires Separate from Gripping Area.

Prevent tubing and wires from interfering with the gripping area and significantly reduce the chance they could be disconnected.

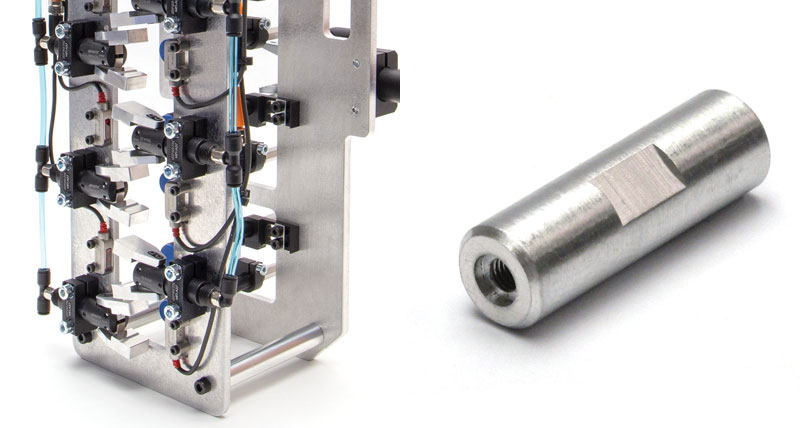

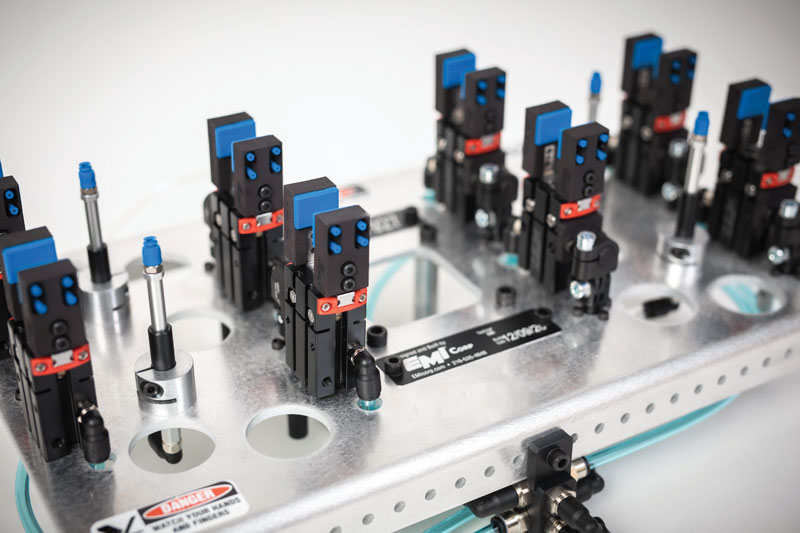

Lightweight Construction with Low-Profile Slides.

Laser-Cut plate construction allows for a lightweight option for use with pneumatic mini-slides. ZE-P slides help adjust cavity spacing after ejection or to reduce the overall footprint of the EOAT to work around mold clearance limitation.

Passing the Savings on to You.

EMI’s in-house laser cutting and 3D printing service allows us to provide considerable time and cost savings without sacrificing quality.

Clamps for Laser-Cut Plate EOAT

Clamps can be used on both front and back of plate. Available in Ø10, Ø14, Ø20, and Ø30mm diameters. Compatible with our wide range of end-of-arm tooling components.

EOAT Plate Standoffs

We offer two types, precision stand-offs mount with M5 bolts and optional centering sleeves. Standard stand-offs require M6 bolts and do not accept centering sleeves. Centering sleeves should be used when a tighter tolerance is required. For instance, in insert loading applications and degate operations.

Contact us for custom stand-off lengths.

S2K Commerce - Products Dropdown

- ${title}

S2K Commerce - Shopping Cart

- ${title}