Z6_EL9QHKG10GPM20IJGE61AK10O0

Z7_I8001C80M82D40A3IJJSN11012

S2K Commerce - Products Dropdown

- ${title}

Loading...

Z7_I8001C80MOVHE0AP2AJ17A3084

S2K Commerce - Shopping Cart

- ${title}

Loading...

Z7_EL9QHKG10GPM20IJGE61AK10S5

S2K Commerce - Order Entry

- ${title}

Loading...

Home

>

EOAT for Cobots

>

Quick Changers

>

Automatic Quick Changer - SmartShift

> 8466 SmartShift Gen III Automatic Quick Changer

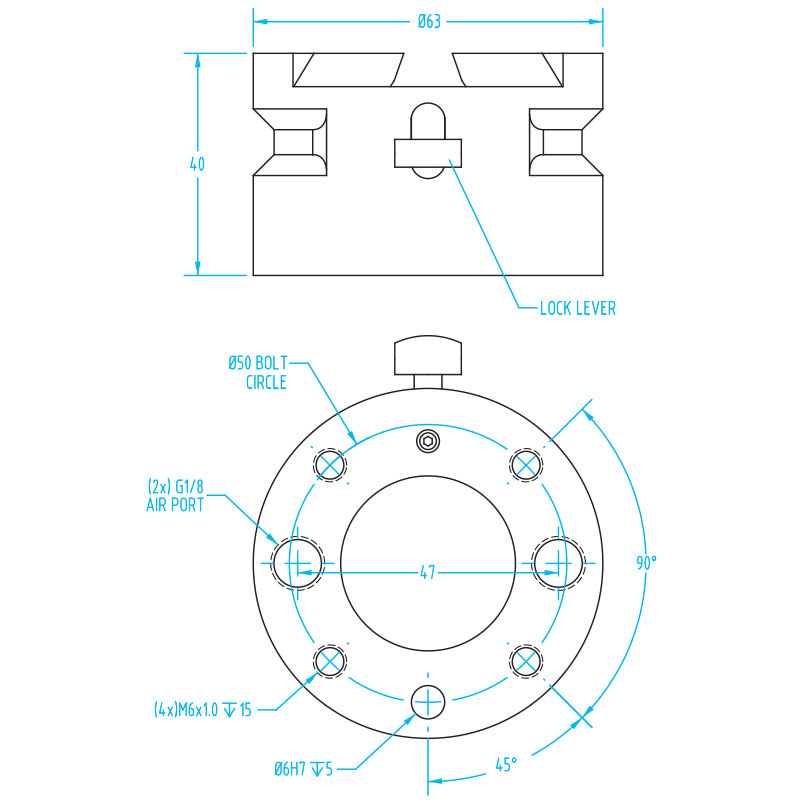

8466 SmartShift Gen III Automatic Quick Changer Tool Side (EOAT Side)

Item #:SS 2120

Available: In Stock

Gen III SmartShift with a vacuum EOAT that requires electrical connection, pneumatics and a vacuum-actuated soft gripper. Tool pockets and framing can be built around your specific application.

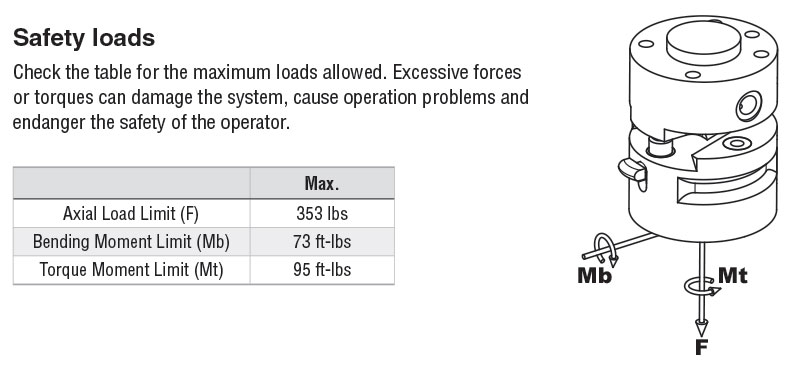

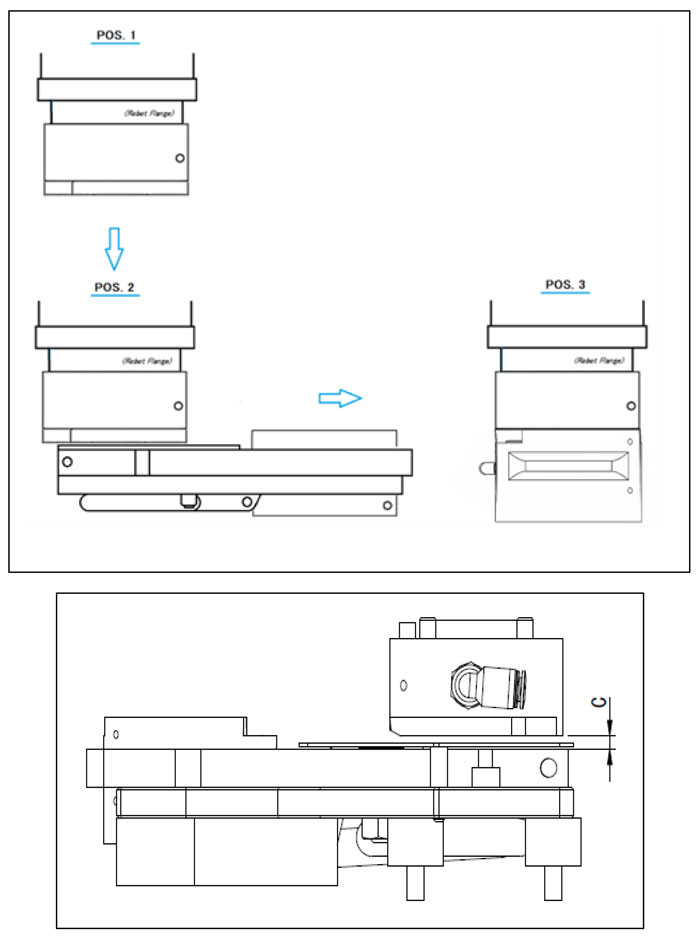

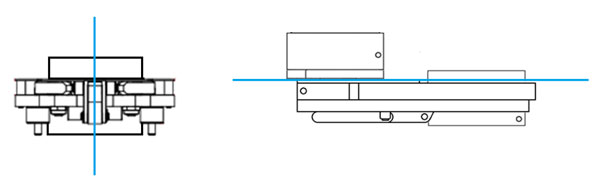

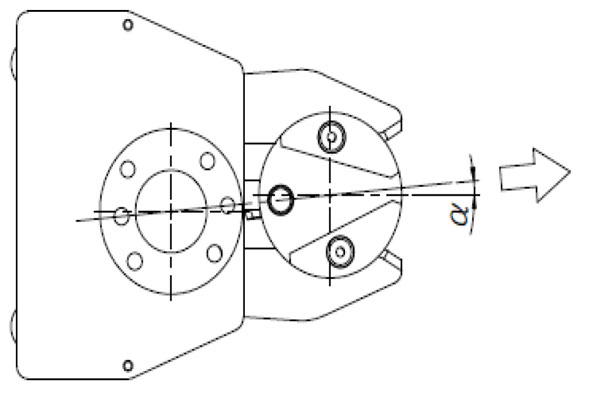

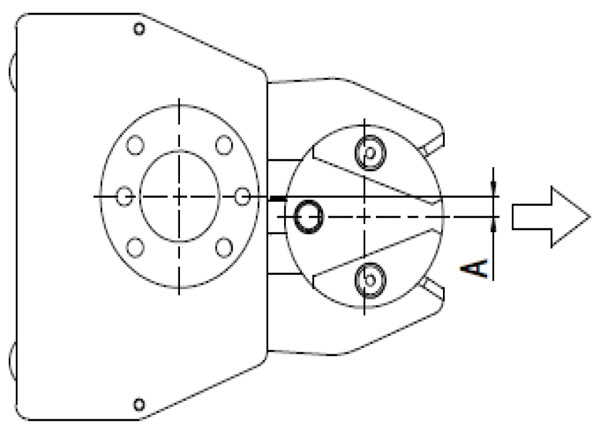

SmartShift automatic tool changers feature a clutch-driven engagement that enables mechanical, pneumatic and optional electric connections. No need for compressed air or electricity for coupling, and available as a kit or a la carte, in two different payload capacities. Automatic Tool Changers require some level of added integration, and we encourage you to partner with our EOAT Engineers to ensure a seamless implementation.

402.00

Each

Quantity:

- 255g

- Recommended for robots handling payload up to: 110lb (50kg)

- 0.05mm repeatability

- No electricity required when changing tools via unique wedge mount.

- Equipped with an air interface allowing easy mounting of many end effectors

- Includes mounting hardware.

- Reference SmartShift: 2120